Eco-friendly Coating for Preservation of Tropical Fruits

KEY INFORMATION

Sustainability - Food Security

TECHNOLOGY OVERVIEW

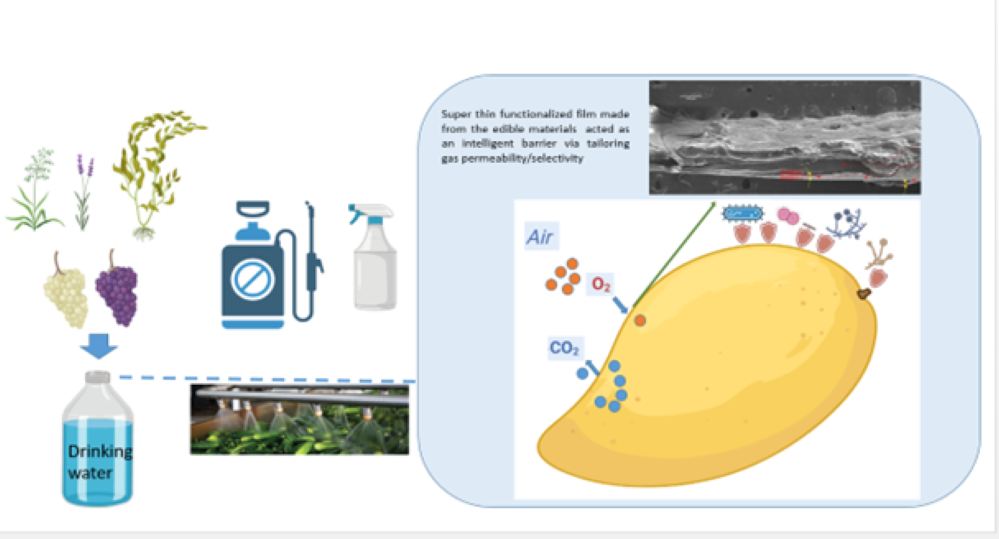

Globally, the post-harvest loss of tropical fruits due to short shelf life is estimated to be around 30-50% of total production. This translates to approximately 30 million tons of fruit wasted each year. The economic cost is substantial, amounting to billions of dollars annually, affecting producers, retailers, and consumers due to reduced availability and increased prices. Proliferation of fungal and bacterial population further adversely impact the shelf life and fruit health. Our innovation offers tailored, edible coating using regulatory approved ingredients specific to the fruit family and microbiomes observed in the farms. Tests conducted in labs and farms over the past two years have provided positive results for tropical fruits such as mango, avocado and papaya in doubling shelf life. This solution has multiple benefits to the stakeholders in the industry value chain. The farmer and aggregator can sell with better assurance to wider export markets and also charge a premium for fresher, tastier and longer lasting fruits. This also provides more time for retailers to sell the produce and to reduce dependency on cold storage and costly supply chain management. This innovation contributes significantly towards better food security and sustainability goals. The technology provider is seeking to conduct further trial with farmers, aggregators in Asia to enhance their solution.

TECHNOLOGY FEATURES & SPECIFICATIONS

Our fruit coating technology utilises ingredients that are vegan, halal, and previously determined to be generally recognized as safe by regulators. These priviledged coatings extend shelf life by controlling water loss, texture deterioration, microbial growth, respiration (O2 and CO2 permeability throught the skin), and senescence processes (modification of internal atmosphere). The team works through the microbial dynamics at each stage of the supply chain, develops and validates region-specific targeted interventions, enhancing the efficacy of our coatings. In summary our solutions enable healthier, fresher and longer lasting tropical fruits through effective control over:

- Dehydration (We keep the water in to delay the fruit from drying out)

- Oxidation (We balance the gases movement)

- Microbial and pathogen growth (We make it difficult for bacteria, yeast, and mould to adversely impact shelf life)

The technology provider is looking for collaborators such as retailers, aggregators, importers to farms, distributors and exporters. The technology provider is open for collaborations with like-minded individuals and organisations, specialising or concerned about food security and fruit wastage as a key pressing global challenge.

POTENTIAL APPLICATIONS

- Fruit postharvest processing; fresh agricultural products; fruit exports

- Widen supply chain options for importers, retail chains and wholesalers

- Exporters, aggregators or farmer to enable healthier longer lasting fruits for consumers who do not need to consume in a hurry.

Market Trends & Opportunities

Nearly a third of the global fruits produced continue to end up in spoilages. Global trade combined for Avocado, mango and papaya exceeds $40b. This represents a significant global market opportunity for the solution, when by investing say 5% of the spends, 20 to 30% wasted spoilage can be saved. This presents an attractive global market potential for $100m potential revenue, considering a conservative 5% of market share*. In Asia alone, due to inadequate supply chains, cold storage and climatic conditions, the fruit losses are even higher. With increasing consumer awareness, fresh tropical fruits are also the most consumed fruits in Singapore and nearby regions. A couple of scenarios below depict the ground-up market potential, considering just for one fruit (papaya or avocado) in these countries. This potential will only be enhanced further once the added benefits of reduced dependence on packaging, transportation and cold storage are considered.

|

Market for Papayas in Singapore |

S$37.1M |

|

Retailers’ potential savings from using our solution |

S$5.4 – 11.2 M |

|

Market for Indonesian Avocados |

S$637 M |

|

Retailers’ potential savings from using our solution |

S$72 – 153 M |

Thus, starting off by addressing the challenges faced in Singapore and Asia, the adoption could be expanded for catering to global markets, leading to a multi-million potential in the years to come.

* Major Tropical Fruits: Market Review Preliminary Results (2023), FAO

Unique Value Proposition

Technology: Our technology revolves around proprietary edible coatings derived from natural plant materials that have antibacterial and antifungal properties. This innovative approach forms a protective film barrier around fruits, significantly protects the fruit from bacterial and fungal growth, and slows down water loss and oxidation—the primary causes of spoilage. Unlike competitors which do not tackle bacteria or fungal infection, limit efficacy or rely on additives or gases to regulate ethylene levels or employ specific packaging solutions, our technology is a one-step process in the supply chain. This unique technology preserves the natural freshness and quality of produce and reduces the need for refrigeration and synthetic preservatives, which can lower overall operational costs.

Business Model: We aim to spin off this technology and will operate on a business-to-business (B2B) model, collaborating closely with growers, suppliers, and retailers across the food supply chain. We will generate revenue through licensing our technology and sell our proprietary coatings to partners, alongside providing consulting and integration services. This model allows the technology to scale its impact by embedding our technology directly into existing supply chain processes, optimizing efficiency and reducing food waste.

Cost Efficiency: Our technology offers cost efficiency by extending the shelf life of produce without requiring extensive cold chain infrastructure or costly equipment. By reducing the frequency of spoilage and waste throughout the supply chain, we help partners save on losses associated with unsellable produce and logistical expenses related to cold storage and transport. This cost-effectiveness aligns with market demands for sustainable solutions.