Efficient Plastic Sorting with AI and Hyperspectral Camera

KEY INFORMATION

Waste Management & Recycling - Industrial Waste Management

TECHNOLOGY OVERVIEW

This invention addresses a significant challenge in the field of plastic resin identification and sorting, a critical issue in material recovery facilities (MRFs) and industrial plastic sorting.

Traditional methods of sorting plastic resins are often inefficient and prone to errors, leading to contamination and reduced quality of recycled materials. This technology introduces a novel AI training method specifically designed for plastic resin classification using near-infrared (NIR) spectroscopy. The approach leverages self-supervised learning and masked signal modeling (MSM) to enhance the accuracy and robustness of deep learning models in identifying various plastic resins, based on their spectral signature data.

One of the unique aspects of this technology is its integration with a rotary sorting system, which significantly improves the speed and precision of sorting operations in MRFs. By automating the resin identification process with accuracy of up to 95% and reducing reliance on manual sorting, this technology helps facilities achieve higher purity in recycled materials, addressing a critical need in the recycling industry.

The technology owner is seeking to collaborate with industry partners operating MRFs and uses a rotary sorting system to integrate and perform test-bedding of the technology.

TECHNOLOGY FEATURES & SPECIFICATIONS

High Accuracy: The AI model achieves over 95% accuracy in plastic resin classification, leveraging near-infrared (NIR) spectroscopy combined with deep learning techniques.

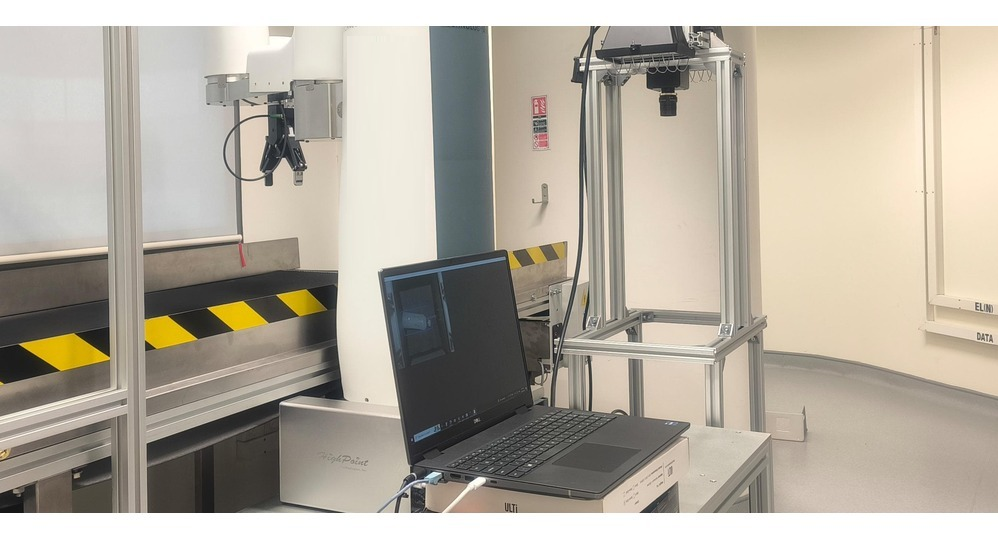

Modular and Scalable Design: The system's modular, stackable design allows easy integration into existing facilities and scalable expansion, from small local MRFs to large industrial plastic sorting plants. It can be combined with robotic arms or human-operated stations, offering a flexible, customised solution that adapts to specific operational needs.

Real-Time, High-Speed Sorting: The integration of a rotary sorting system enables real-time processing, handling up to 2 plastic samples in 1 second. This speed and efficiency surpasses traditional conveyor-based systems, making it ideal for large-scale operations.

Energy Efficiency and Cost Reduction: This rotary system is energy-efficient, reducing operational costs by up to 30% compared to conventional methods. Its low maintenance requirements further minimise downtime, making it a cost-effective long-term solution.

Sustainability Impact: By improving sorting accuracy and efficiency, the technology supports sustainable recycling practices and reduces the environmental footprint of plastic waste management.

POTENTIAL APPLICATIONS

- Waste management and recycling

- Manufacturing and production

- Environmental and sustainability applications

Market Trends & Opportunities

It is estimated that by 2025, the global market for machine vision technologies to improve material sorting process will reach a value of US$1.5 billion, with a compound annual growth rate (CAGR) of 25% between 2020 and 2025 – Picvisa.

Unique Value Proposition

Utilising advanced AI models trained with near-infrared (NIR) spectroscopy and incorporating self-supervised learning with masked signal modeling (MSM), this technology achieves over 95% accuracy in resin classification. This precision surpasses existing methods, reducing contamination and improving the purity of recycled materials.