Thin-Film Composite Hollow Fiber Membranes for Oxygen Enrichment

KEY INFORMATION

Sustainability - Sustainable Living

TECHNOLOGY OVERVIEW

Oxygen enrichment membrane technology is emerging as a promising, cost-effective, and energy-efficient method for producing oxygen-enriched gas (OEG) with oxygen purities of 30-45%. Traditional oxygen production methods, such as cryogenic distillation and pressure swing adsorption, are often costly, energy-intensive, and complex, making them less suitable for applications requiring moderate oxygen enrichment.

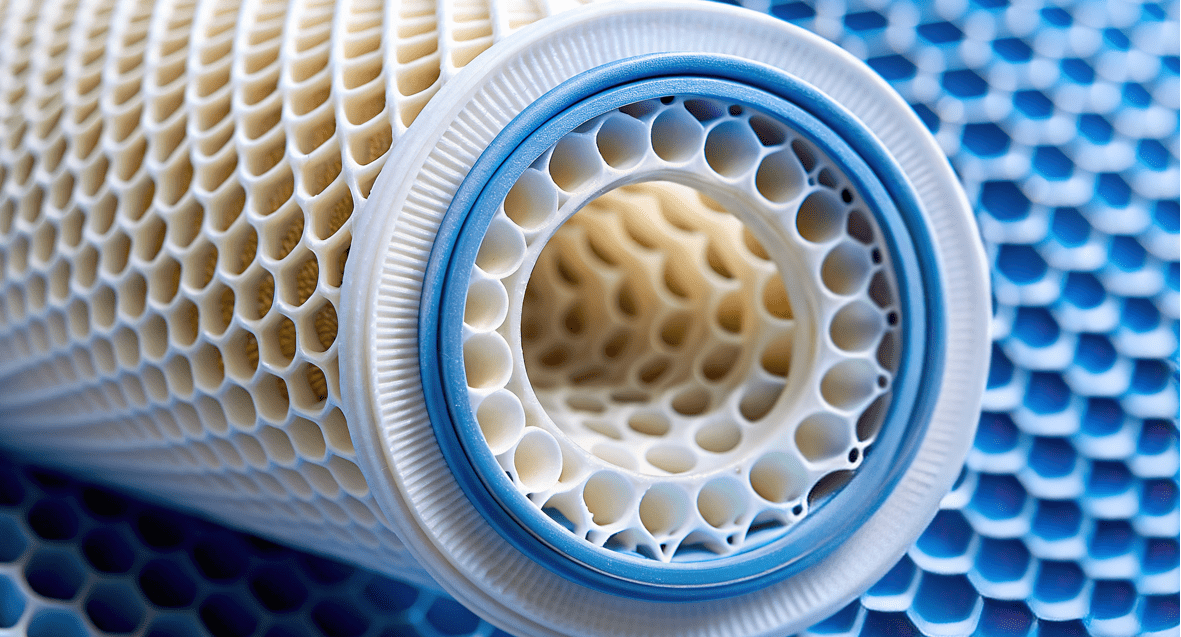

This innovative technology addresses these challenges through a thin-film composite (TFC) hollow fiber membrane that incorporates a novel use of polydimethylsiloxane (PDMS) as a selective layer on a polyethersulfone (PES) substrate. The PDMS selective layer is applied using a flow coating technique, which is both simple and scalable, allowing for consistent production of high-performance membranes. The technology was upscaled to commercial-sized membrane modules producing 15-53 Nm³/h of OEG with oxygen purities between 31-38%. The membrane system operates at ambient temperatures and pressures, offering significant energy savings and reduced operational costs compared to traditional methods.

The benefits of this technology are substantial, including improved cost-effectiveness, enhanced energy efficiency, and flexibility in scalability, making it suitable for a wide range of industrial applications.

The technology owner is seeking collaboration with membrane manufacturers to further scale up this innovative technology, and with end-users who have a demand for oxygen-enriched gas with 30-40% O₂ purity.

TECHNOLOGY FEATURES & SPECIFICATIONS

-

Two-Piece Module Design: Features a two-piece configuration with central coupling, enhancing compatibility with the TFC membrane and PDMS coating for a uniform, defect-free selective layer.

- Simplified Maintenance: Allows replacement of only the affected half of the module, reducing maintenance costs.

-

Prototype System: Comprises 20 modules in a containerized skid with an air compressor, wet air receiver, refrigerated air dryer, and scaffolds.

-

Operational Efficiency: Operates at 5 bar, producing OEG at 15-53 Nm³/h with 31-38% oxygen purity.

-

Integration with OEG Gasifier: Replaces part of the liquid oxygen in municipal solid waste gasification, achieving 34.5-45.2 Nm³/h flow rate and over 20% liquid oxygen replacement in a 7-day test.

POTENTIAL APPLICATIONS

With the ability to generate oxygen-enriched gas (OEG) with oxygen purity levels between 30 to 45% at a low working pressure of 5 bar, the TFC hollow fiber membrane technology offers versatile commercial applications across various industries:

- Healthcare Sector: Suitable for medical uses that require oxygen purity levels of 30 to 40%, such as oxygen therapy and respiratory support.

- Wellness Industry: Applicable in nitrox diving, oxygen bars, and training rooms, where controlled oxygen environments can enhance user experience and performance.

- Combustion Manufacturing Sectors: Ideal for furnace combustion, wastewater incineration, and petrochemical processes that benefit from oxygen-enriched air with 25 to 35% oxygen purity, leading to improved combustion efficiency and reduced emissions.

- Aquaculture Industry: Used for aeration in recirculating aquaculture systems (RAS), enhancing oxygen levels in water to support healthier and more productive aquatic environments.

Additionally, the technology produces a pressurized nitrogen-enriched retentate stream of nitrogen purity greater than 85%. This nitrogen-enriched gas stream can be utilized in:

Chemical and Oil & Gas Industries: Employed as an inert purge gas to prevent combustion and oxidation reactions during various processes.

Food and Refinery Industries: Used as a blanketing gas to protect sensitive products from oxidation, moisture, or contamination, ensuring product quality and safety.

These diverse applications highlight the technology's flexibility and potential to enhance operational efficiency, safety, and sustainability across multiple sectors.

Unique Value Proposition

- Cost-Competitive for Moderate O₂ Purity and Lower Flow Rates: Offers clear cost advantages for applications requiring OEG with 30-40% oxygen purity and flow rates below 1200 Nm³/h, making it ideal for retrofitting existing plant.

- Low Operating Pressure: Generates OEG at a lower pressure of just 5 bar, compared to 7-14 bar for existing technologies, enhancing safety and reducing operational costs.

- Easy Installation and Low Set-Up Costs: Simple to install with minimal upfront investment, reducing barriers to adoption.

- Quick Start-Up: Delivers oxygen-enriched gas of the required purity immediately upon start-up, improving operational efficiency and responsiveness.

- Modular and Flexible Design: The modular system allows customization to meet a wide range of OEG demands, providing flexibility in application across various industries.

- Low Maintenance and Easy Operation: Requires minimal maintenance, simplifying operations and reducing downtime.

- Portability: Can be designed as a portable system, enabling on-site oxygen generation for diverse applications.