Lixiviant for High Extraction of Silver from Silver-Coated Solid Wastes

KEY INFORMATION

Waste Management & Recycling - Industrial Waste Management

TECHNOLOGY OVERVIEW

Strongly corrosive acids and highly toxic cyanide-based solutions are currently the most commonly used lixiviants for extraction of silver from solid wastes through hydrometallurgy. While acids are generally able to achieve high extraction of silver, it is non-selective and leaches most of the other metals present, resulting in a complex mixture that needs rigorous segregation and purification downstream. Cyanide solutions are comparatively more selective towards silver but require costly safety infrastructure and measures to be put in place as they generate large amount of hazardous wastes.

The lixiviant developed offers a more user and environmentally friendly means to efficiently extract silver selectively from silver-coated solid waste. The formulation is free of cyanide and omits the use of any strong acids, making it relatively easy to handle and eliminates the safety, health and environmental problems associated with the use and post-treatment of conventional lixiviants, as the waste stream is mildly acidic and can be easily treated as normal acid waste. The raw chemical materials are also easily available in the market.

The technology provider is seeking industry partners to test-bed the lixiviant and is open to license the technology to interested partners.

TECHNOLOGY FEATURES & SPECIFICATIONS

- Free of cyanide

- Contains low concentrations of organic acids and no strong acids

- Non-fuming and extracts under mild temperatures ≤ 40°C

- Contains stabilisers to reduce reagent consumption

- Allows high purity silver to be recovered from the leachate by conventional means such as precipitation & reduction

- ≥97 wt.% of silver extracted with saturation concentration of >10 g/L at 40°C

- Extraction is fairly selective, with silver constituting a major 85 – 98% of the metals leached

POTENTIAL APPLICATIONS

This technology can be applied for extraction of silver from:

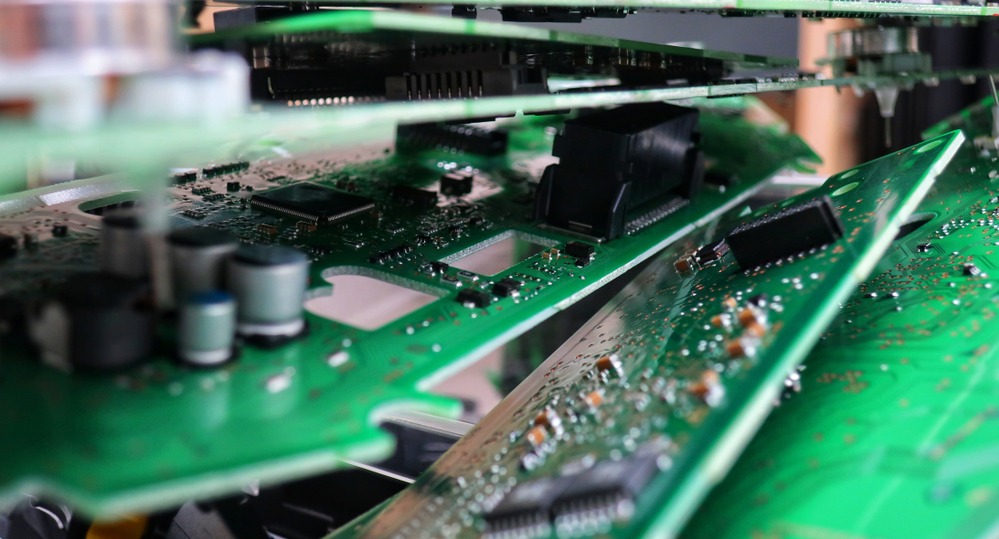

- Electronic wastes, such as printed circuit boards, connectors, lead frames etc.

- Industrial wastes, such as photographic films, solar panel wafer etc.

- Recovered silver can be sold or recycled for other uses.

Market Trends & Opportunities

Silver is widely used in the manufacture of numerous products such as electrical and electronic devices, photovoltaics (PV) modules, solders, photographic films and jewelleries. The demand for silver is forecasted to grow with its use in 5G-infrastructure and upcoming intelligent electronics, as well as in PV modules as more countries adopt renewable energy to counter climate change.

To meet the increasing demand for silver, recycling from secondary sources such as electronics and industrial wastes is essential. Increasing regulations put up worldwide that mandate the recycling of electronic wastes, accounts for the bulk of secondary sources of silver.

Hydrometallurgy offers a way to recycle silver at a relatively low cost and smaller scale. With the employment of an effective lixiviant that is able to achieve high and selective extraction of silver from these secondary sources, it ensures that the most value is drawn from them. Additionally, the omission of strong acids and cyanide in the lixiviant eliminate the need for costly safety infrastructure and treatment of toxic waste streams generated.

Unique Value Proposition

- Lixiviant can be directly employed in existing operating line

- Works under mild operating conditions

- Does not generate highly toxic waste streams

- Recovered silver in high purity