Cost-Effective Protective Coating Enhancing Durability of Electrode Catalyst

KEY INFORMATION

Manufacturing - Chemical Processes

TECHNOLOGY OVERVIEW

Electrolysis has diverse applications across various sectors, such as household and industrial electrolyzed water treatment, soda electrolysis, electrolytic plating, electrodeposition, and hydrogen generation. In electrolysis using insoluble electrodes, the electrocatalyst acting as the reaction field for the electrode reaction undergoes gradual abrasion. Given the high cost of precious metals (i.e., platinum group compounds) used as catalysts, protecting the catalyst and reducing the wear rate are crucial for extending the lifetime of electrodes and reducing the maintenance cost.

Current technologies include multilayer electrodes that have a surface layer of noble metal oxide on the electrocatalyst to reduce catalyst wear. However, this method proves more expensive than ordinary insoluble electrodes. Additionally, the surface layer cannot be recoated. To address the challenge, the technology owner has developed a proprietary protective coating that effectively protects the catalyst on the surface of existing insoluble electrodes. This solution enables effective electrode protection through an inexpensive coating, reducing catalyst consumption and electrode replacement frequency. The coating can be reused by recoating the electrode, also contributing to the perspective of “Circular Economy”.

The technology owner is seeking R&D collaboration with industrial partners such as electrode manufacturers, coating manufacturers, and companies utilising insoluble electrodes in electrolysis, especially electrolytic plating and metal recovery.

TECHNOLOGY FEATURES & SPECIFICATIONS

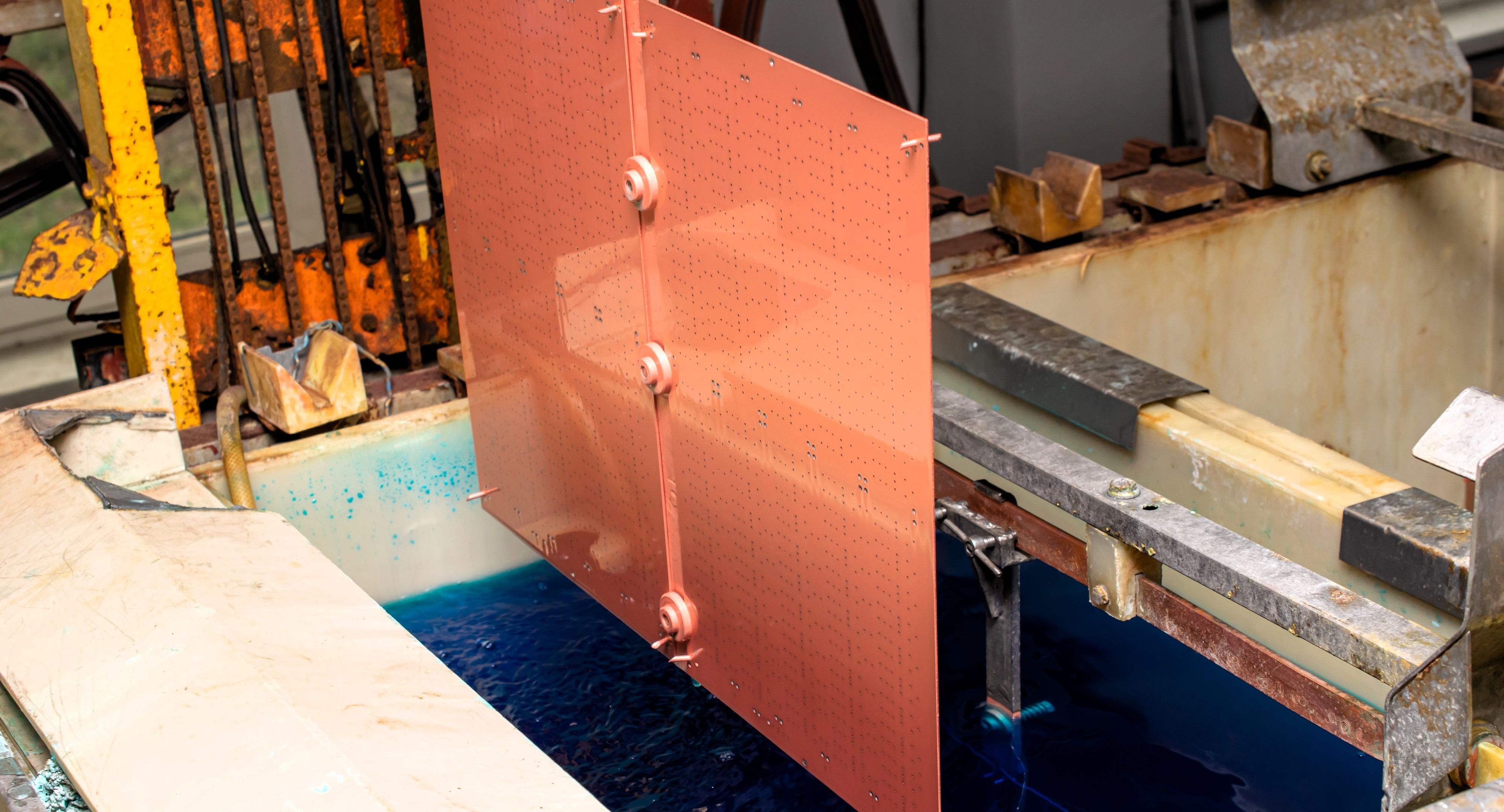

This unique coating, made of special silicone and conductive particles, can be applied to the catalyst surface and cured to reduce catalyst wear. Key features of this technology include:

- Improved electrode durability: double the replacement interval

- Excellent chemical resistance: capability to withstand harsh liquids such as strong acids and strong alkalis

- Optimal performance: good heat resistance, conductivity, and adhesion to the base material

- Efficient development: shorter development time and lower implementation cost compared to alternative methods such as electrolytic control and diamond coating

- Cost-effective solution: reduce maintenance cost and utilisation loss in the upstream process of electrolysis

- Circular economy contribution: reusable by recoating the electrode

POTENTIAL APPLICATIONS

This technology can be used in handling harsh liquids such as strong acids and strong alkalis, addressing the challenge of electrode durability. It is mainly intended for the recovery of metals through electrolysis, especially targeting aqueous solutions containing metal ions. This is particularly useful for processes such as electrolytic plating and etching effluents in semiconductor manufacturing.

In the future, the technology owner is also exploring the potential applications of this technology in water electrolysis electrodes and the use of conductive coatings beyond electrodes.

Unique Value Proposition

- Double the lifetime of the electrode using an inexpensive coating

- Can be reused by recoating the electrode

- Reduce the replacement frequency and maintenance cost

- Adaptable to existing coating (painting) facilities without modification