Revolutionizing Cell Therapy Cultivation: Next-Generation Feeder-cell Mimicking Platforms for Cell Modulation

KEY INFORMATION

Life Sciences - Industrial Biotech Methods & Processes

TECHNOLOGY OVERVIEW

Immune cell activation and expansion for cell therapy is a strictly regulated process. It demands costly and labour-intensive optimization of cell culture conditions. Major limitations of these processes are cell quality and results consistency. Large amounts of expenses were spent on culture conditions, cell characterizations and quality control (QC) with differing culture protocols and recipes in growing CAR-T cells.

This technology has established a standardized platform through its feeder-cell mimicking feature that could screen culture conditions for diverse cell types and patient source more rapidly at lower costs. Both feeder-cell based system and feeder-free system poses respective challenges of contamination or insufficient growth signals.

To address this gap, a modular, all-signals-in-one microbead-based platform has been developed for the next-generation cell therapy R&D and translation. In this delivery platform design, the modular feature allows rapid ‘plug-and-use’ of multiple surface and soluble signals to grow T-cells ex vivo without the need for extensive setup and integration of culture protocols. This platform aims to provide a seamless and straightforward cell culture experience for the industrial and academic research users to discover new types and applications of immune cell therapy.

Additionally, the all-signals-in-one synthetic platform mimics the natural antigen presenting cells to activate and expand T-cells on dish, allowing cell manufacturers to ‘mix-and-grow’ immune cells with reduced effort or technical expertise. This aims to improve the cost-effectiveness and scalability of cell therapy manufacturing.

The technology provider is seeking collaborations with cell therapy CDMOs/CMOs in licensing and various R&D developments.

TECHNOLOGY FEATURES & SPECIFICATIONS

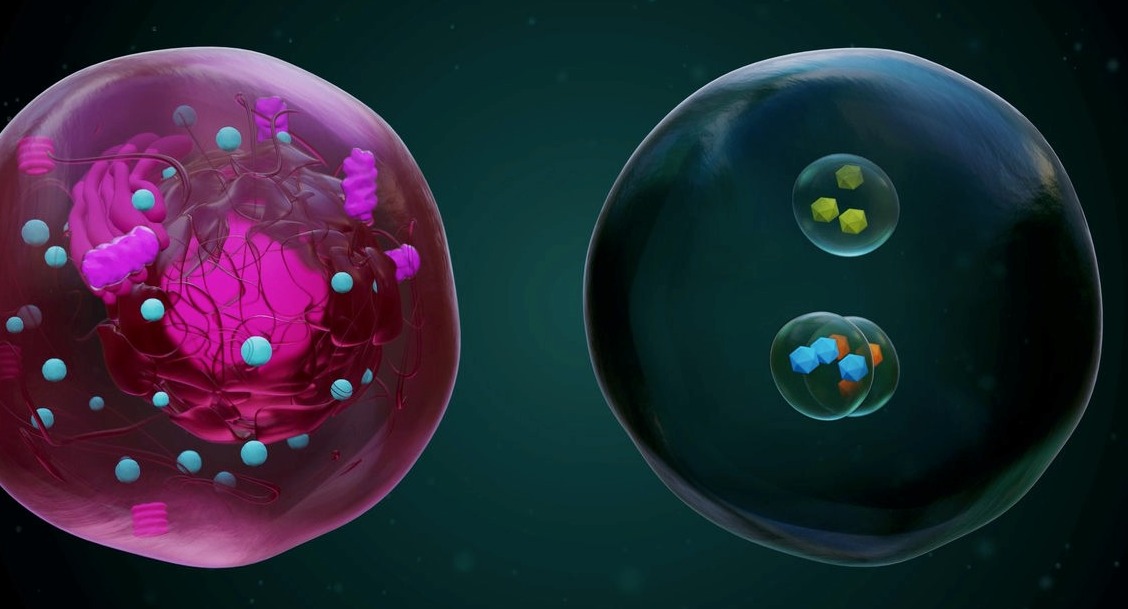

The proprietary microbead has 4 modules: the core, shell, surface and soluble signals which are assembled into an artificial cell.

- The core is a hydrogel microparticle made of chemically modified polysaccharides, produced via membrane extrusion method or high-throughput microfluidics assisted technology to control the particle sizing (from submicron to microns) and uniformity.

- The shell consists of fluidic lipid membrane surrounding the hydrogel microparticle via proprietary coating technology. The lipid shell can be made of purely synthetic lipid components, such as POPC, biotin-PE, natural lipid extracts from cellular membrane or exosomes, or hybrid to fine-tune the stability, fluidity and bio-functionality.

- The surface signals are docked on the shell via biotin-avidin interactions. These signals may include but are not limited to, anti-CD3, anti-CD28, anti-CD2, anti-CD137 for CAR-T cell production or different surface signal combinations for other immune cell types.

- The soluble signals can be loaded into the hydrogel microparticle, such as cytokine, growth factors or other chemical modulators. The release profile can be adjusted with the hydrogel degradation kinetics.

From a scale up production point of view, each module could be mass produced and stored independently and assembled into the final microbead product for ex vivo cell activation and expansion. The resulting all-synthetic microbead products are shown to be biocompatible and biodegradable ex vivo and in vivo. Therefore, they have the potential to be used in in vivo T-cell activation and expansion.

POTENTIAL APPLICATIONS

The proprietary microbead-based platform functions as an artificial cell, with its fluidic membrane surface signals presentation and controlled-released soluble signals. The platform application includes but not limited to:

- Cell therapy manufacturing: Microbeads can be used to support and supplement ex vivo T-cells activation and expansion.

- Cell-based therapies and regenerative medicine: Microbeads can be engineered to mimic the functions of specific cell types, such as T-cells for immunotherapy, pancreatic cells for diabetes and glial cells for neuron repair.

- Versatile high-throughput screening platform bridging in-silica signals discovery and in-vitro validation: The ‘plug-and-use’ microbead-based platform feature, together with the versatility avidin-biotin technology and accessibility of commercial biotinylated recombinant proteins and antibodies enable rapid in vitro tests of novel biochemical signals and combinations on cell functions.

Market Trends & Opportunities

Cell therapy is the next pillar of medicine for the treatment of chronic diseases, such as cancer, autoimmune disorders etc. The cell expansion market was valued at 41.3B USD in 2021 with a CAGR of 12.6%. Nonetheless, many cell therapeutics are still in the discovery and pre-clinical phase. The clinical translation is hampered by suboptimal culture process, unstandardized protocol, limitations of research tools and ex vivo signals delivery platform and high demand of technical expertise. The predominant player in cell expansion and activation market is the magnetic microbeads with emerging alternatives such as antibody tetramers, polymeric nanomatrix, nanosystems with varying shapes/size/stiffness to expand the cell growth tools, facilitate R&D and translational research of cell therapy.

Unique Value Proposition

The microbead platform technology mimics cell structures, allows rapid customization of surface and soluble biochemical signals, and enable automation manufacturing process to transform donor cells into therapeutics. The platform is designed to fit existing cell manufacturing automation modalities in the following ways:

- Microbeads in suspension form for use in bioreactors.

- All-signals-in-one microbead system to mimic feeder cells to facilitate cell activation and expansion.

- By-passing of de-bead step to allow adjustable degradation kinetics of microbeads such as active degradation (allow users to degrade beads anytime) or passive degradation (hydrolysis within the hydrogel microparticles).

- Degraded hydrogel products are polysaccharides, protein, and lipids, which can be removed via standard cell washing process.

Furthermore, this technology has shown to increase both CAR-T cell persistence and total number of T-cell production. This platform will accelerate the speed for validating novel soluble and surface signals identified and elucidated through AI and single-cell sequencing technologies/data from tumour microenvironments, patient immune cells profile etc.

All in all, this platform brings two unique experiences to the research and industrial users, that are ‘plug-and-use’ and ‘mix-and-grow’ to streamline the cell therapy R&D, translation and scaleup production workflow with greater cost-effectiveness without compromising high quality and reliable cell therapy to millions of patients in need.