Coating Of The Anode For Rechargeable Lithium-Ion Batteries

KEY INFORMATION

TECHNOLOGY OVERVIEW

Lithium-ion (Li-ion) batteries are the most developed and widespread rechargeable batteries and is expected to dominate the market in coming years. Despite the wide adoption, Li-ion batteries face challenges that result in degradation of electrochemical performance due to side reaction with the electrolyte, dissolution of electrode components, transformation and pulverization of its structure and so on.

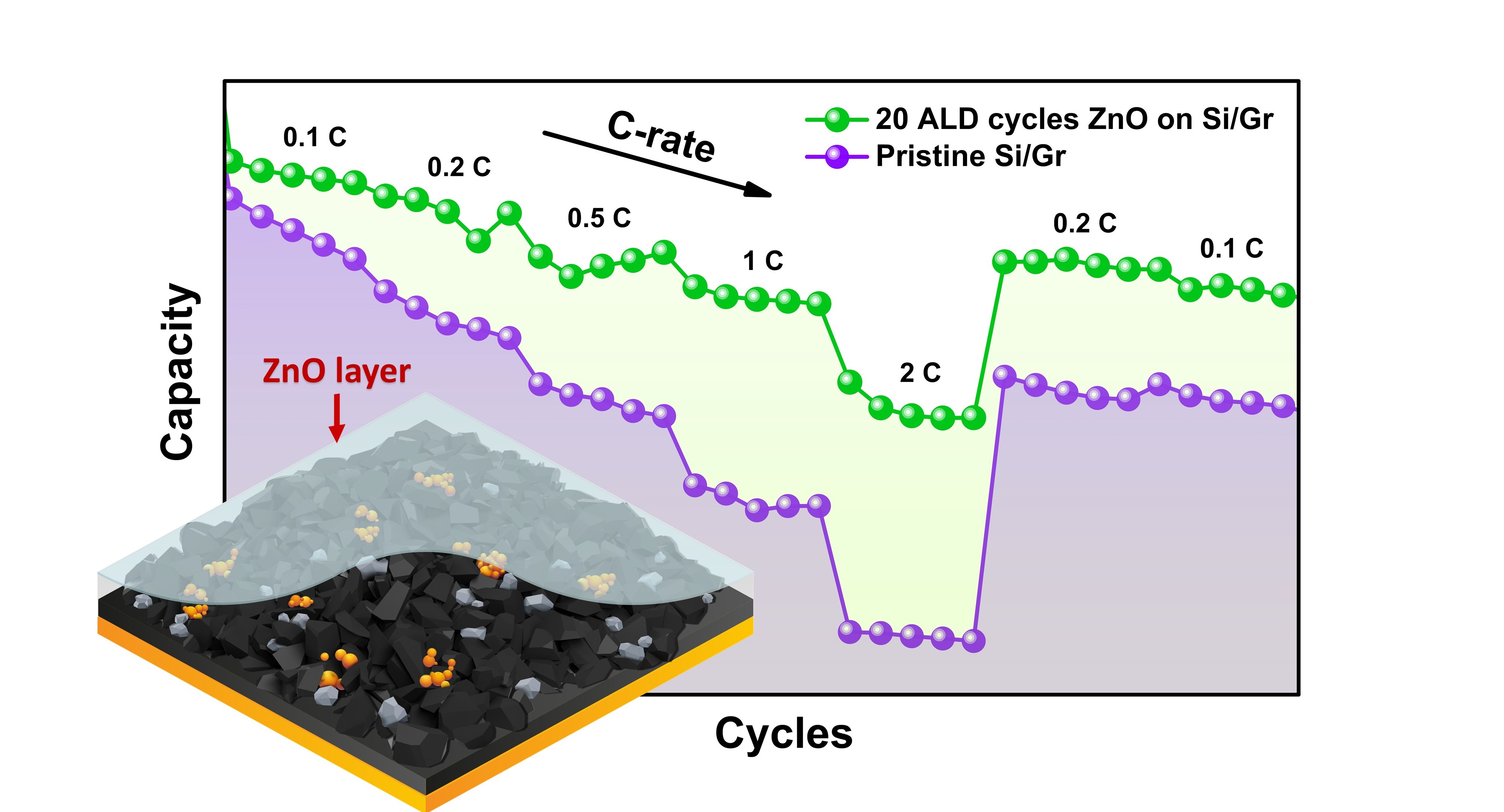

The patent pending technology proposed herein aims at improving the performance of Li-ion batteries through the application of ultrathin oxide layers which increases the cycling stability and C-rate capability of lithium-ion batteries. The technology modifies the surface of the silicon-based anode of the Li-ion battery with a thin layer of Zinc Oxide (ZnO) applied by atomic layer deposition (ALD) technology. Typically, the ZnO thickness is of order of few nanometers. The ZnO layer suppress side reactions by limiting the excessive growth of the passivation layer at the anode interface and liquid electrolyte, inhibiting the dissolution of the electrode components, and enhancing conductivity and Li-ion transfer. This resulted in increased battery capacity particularly during fast charging and discharging and increases cycle life of battery.

The technology owner is seeking to license the technology to a battery manufacturing partner who have access to ALD equipment to facilitate the integration of the anode surface modification technology into their battery manufacturing process.

TECHNOLOGY FEATURES & SPECIFICATIONS

A special deposition technology adapted for porous materials should be applied. The deposition take place at the temperature of 100 °C. The technique can be up-scaled to roll-to-roll process suitable for industrial production.

Competitive advantage includes increased service life of the Li-ion battery during fast charging and discharging, elimination of the battery capacity reduction, creation of an artificial protective and corrosion resistant passivation layer.

POTENTIAL APPLICATIONS

The technology can be used in energy storage, especially in the automotive industry. As a part of electromobility (electrical vehicles, bicycles, scooters), it will ensure fast and efficient charging of the battery while maintaining the total capacity and eliminating the drop in battery capacity during charging/discharging cycles.

Market Trends & Opportunities

According to the Strategic Research and Innovation Agenda - BATT4EU up to 900 GWh of batteries is estimated to be produced annually in 2030 only for electrical vehicles (~ 20 000 batteries). After 2035 only electrical vehicles will be presumably produced.

The Global Lithium-Ion Battery market reached about USD 85 billion in 2022 and is projected to grow significantly, reaching a market value of more than USD 400 billion by 2030.

Unique Value Proposition

ZnO coated silicon-graphite based anode offer improvement in capacity over the current state-of-the-art in particular at high charging/discharging rates. Capacity of the ZnO coated anode can be 5 times higher applying fast charging/discharging during 30 min.

.jpg)