Filtration System for Redox-based Lithium Battery Material Recycling

KEY INFORMATION

Energy - Battery & SuperCapacitor

TECHNOLOGY OVERVIEW

Recycling of lithium-ion battery material is becoming an increasing necessity and to execute that task in an environmentally friendly and cost-effective method is as important.

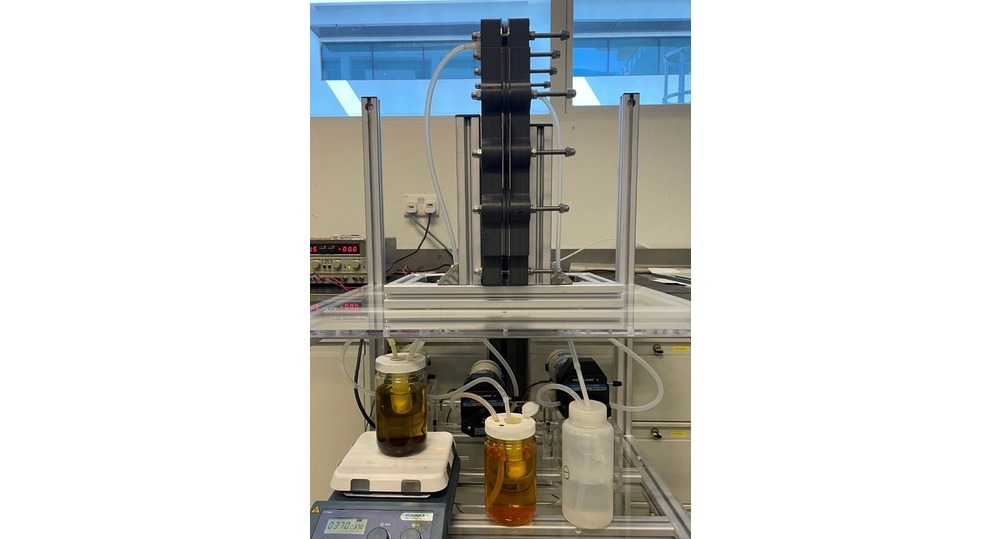

The novel method of recycling spent battery material using a redox flow battery approach requires the solid spent battery material to react with liquid electrolyte in the tank. The proposed technology by a Singapore-based research team relates to an electrolyte tank filtration system designed to allow solid particles to freely mix and react with electrolyte in the tank of the flow battery system, while being filtered and prevented from entering the pump and cell stack. The holder is designed to be simply placed into and removed from the electrolyte tank, and subsequently, for the easy removal of the solid from the holder itself. This innovation will allow the continuous running of the flow battery system while changing the filter periodically.

The research team anticipates that companies planning to utilise redox flow battery recycling method would require the use of such a filter system to reduce the downtime of the entire system. The team is seeking to collaborate with an industrial partner for further research and development of the filtration system and subsequent licensing of the technology for commercialisation.

TECHNOLOGY FEATURES & SPECIFICATIONS

- The electrolyte tank filtration system allows free mixing of electrolyte with solid reactants, while preventing the solid particles from entering the pump and cell with the electrolyte

- Flexibility in addition and removal of multiple filter holders

- Ease of removing filter paper and solid product from filter holder

- Able to run flow battery continuously without having to stop for filter removal, leading to no downtime of the system

POTENTIAL APPLICATIONS

While this technology is designed specifically for the recycling of solid spent battery materials using the redox flow battery system, it can be adapted to be deployed in any flow battery applications that requires filtration of solids reactants from a liquid electrolyte.

Unique Value Proposition

Based on a non-exhaustive secondary research by the team, there is no “state-of-the-art’ filtration system designed for redox flow battery used for battery material recycling. Filtration systems in the market are not specifically made for the purpose of recycling battery material in a flow battery and therefore do not come with the features and the advantages that come with the proposed technology. Present technology can only allow for such filtration batch by batch, causing stoppages and idle time for the entire flow cell system.