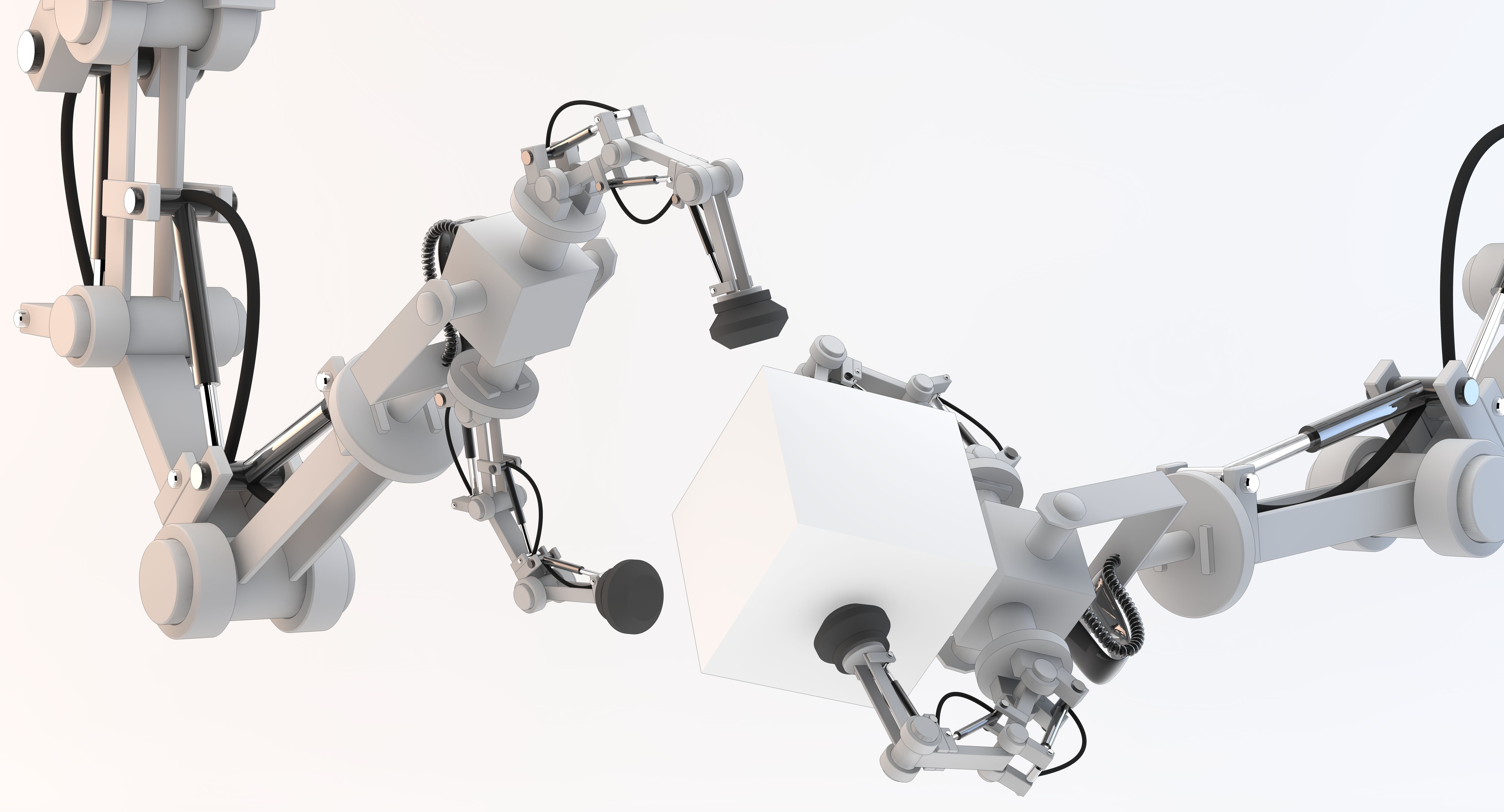

Robotics Grasping Simulation

KEY INFORMATION

Manufacturing - Assembly, Automation & Robotics

TECHNOLOGY OVERVIEW

Grasping technology, often associated with robotics and automation, addresses the challenge of manipulating and handling objects in various environments. The primary problem solved by grasping technology is the ability to securely and accurately pick up, hold, move, and release objects with different shapes, sizes, and materials. This technology is especially crucial in situations where human intervention may be difficult, dangerous, or inefficient. Before the deployment of new models and algorithms in the real world, it would be great to test the algorithm in a realistic simulation environment first.

TECHNOLOGY FEATURES & SPECIFICATIONS

The technology presented is a realistic simulation environment to test a robotic system for grasping and manipulation. Using the simulation environment, the movements of the physical and virtual robots are synchronized. This is done without the need for writing additional code to control the physical robot, which makes real-world deployment seamless and easy. The grasping system is tested in simulation and can easily be deployed in the real world with visualization of real-time feedback on robotics tasks via the same design and simulation platform.

POTENTIAL APPLICATIONS

The technology has potential applications in manufacturing, warehousing, and household robotics, where improving grasp success rates is critical for enhancing efficiency and reducing costs. These environments are often cluttered and contain dynamically moving objects.

Unique Value Proposition

A synchronized sim-to-real platform for robotic grasping and manipulation can be incredibly useful to the industry in several ways:

- Reduced Cost: Traditional methods of developing robotic grasping and manipulation systems require expensive hardware, time-consuming trial-and-error testing, and large amounts of data. A synchronized sim-to-real platform allows for much of this testing and data collection to be done virtually, reducing costs and increasing efficiency.

- Improved Efficiency: With a synchronized sim-to-real platform, researchers and developers can test and fine-tune robotic grasping and manipulation algorithms in simulation before deploying them on physical robots. This can reduce the time required for physical testing and enable more efficient algorithm development.

- Increased Safety: The use of simulation environments can provide a safer testing environment for robotic grasping and manipulation systems, allowing developers to test and refine algorithms without risking damage to expensive hardware or injury to human operators.

- Enhanced Performance: With the ability to test and optimize algorithms in simulation, developers can achieve higher levels of performance in robotic grasping and manipulation tasks, leading to more effective and reliable systems.

- Better Scalability: A synchronized sim-to-real platform can also facilitate the development of more scalable robotic grasping and manipulation systems, as algorithms and methods can be tested and refined in simulation before being deployed on a larger scale.

Overall, a synchronized sim-to-real platform for robotic grasping and manipulation has the potential to significantly improve the efficiency, safety, and performance of industrial robotic systems, leading to greater productivity and cost savings for companies.