Lixiviant for High Efficiency Extraction of Palladium (Pd) from Electronic Waste

KEY INFORMATION

Chemicals - Catalysts

TECHNOLOGY OVERVIEW

The exponential growth of electronic waste (E-waste) generation is proliferating due to the ever-increasing demand for electrical and electronic equipment (EEE) driven by industrial revolution and development. The COVID-19 crisis has further accelerated the shift towards digital transformation, contributing to an upsurge in E-waste generation. To-date, the industrial practices of extracting palladium (Pd) from electronic waste and mining ores rely on hydrometallurgy techniques using highly corrosive acids, typically aqua regia at elevated temperature. The process poses severe hazards to workers and lead to environmental pollution. Aqua regia’s capability to dissolve many various metals results in low selectivity for Pd. Despite ongoing efforts to develop alternative methods, these methods often prove impractical for industrial adoption.

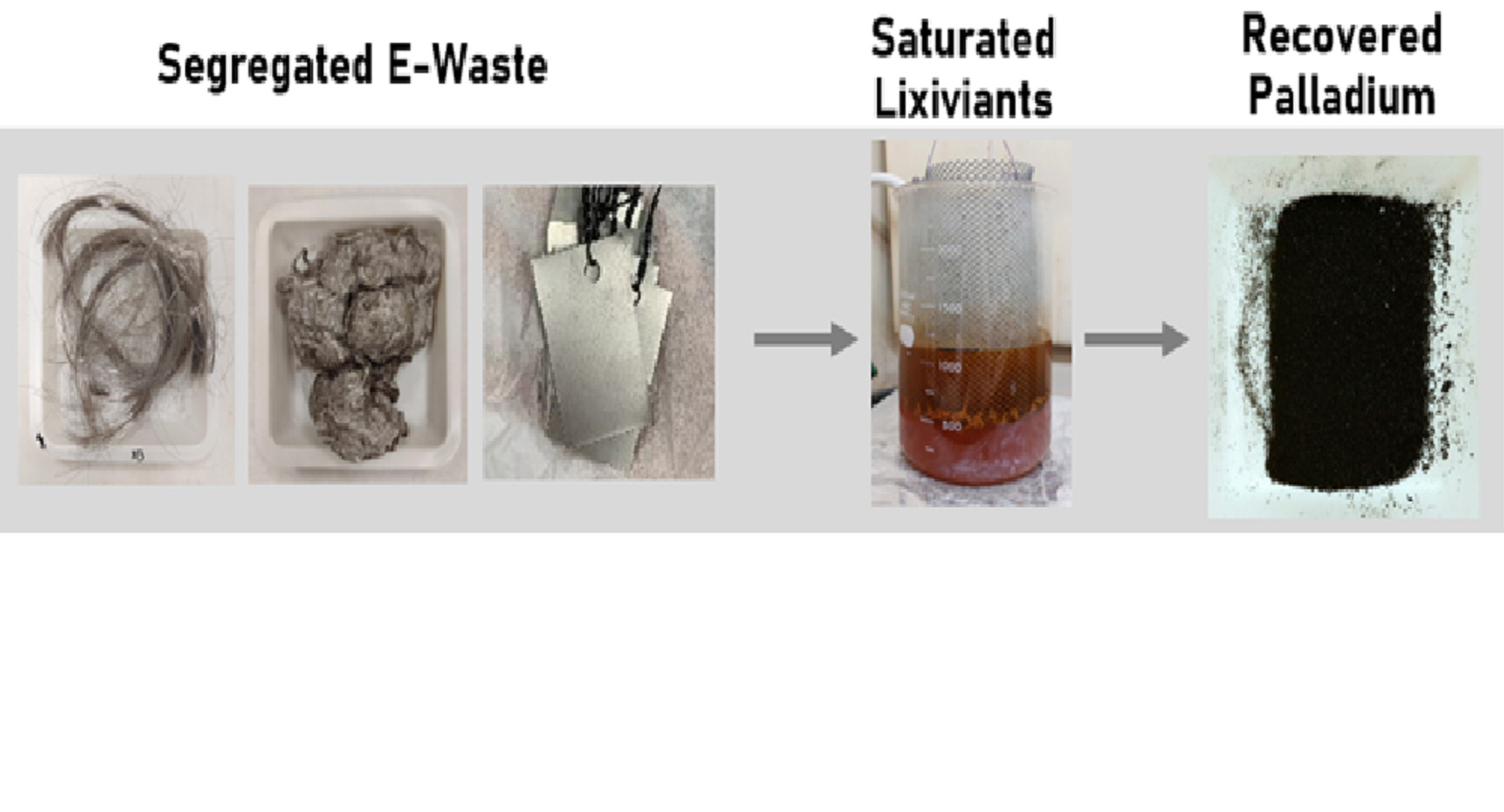

The technology provider has developed a proprietary lixiviant capable of extracting palladium up to 4,000 ppm at saturation with high extraction efficiency and selectivity within 12 hours. This lixiviant is facile, cost-effective, and significantly less corrosive and hazardous compared to current industrial practices. Substituting fuming aqua regia with this lixiviant could enhance the protection of workers and environmental safety. Importantly, the proposed technology is highly compatible with existing hydrometallurgy processes, eliminating the need for companies to change their current infrastructure. An E-waste industry partner has successfully conducted a pilot-scale (5-Litre scale) evaluation, validating the effectiveness and applicability of the lixiviant on their Pd-coated samples.

The technology provider is actively seeking industry partners interested in test-bedding and licensing of this technology.

TECHNOLOGY FEATURES & SPECIFICATIONS

- Low cyanide concentration (< 50 ppm) stabilized in alkaline solution

- Optimal operating temperature of 90°C

- High selectivity (> 86%) and high extraction rate (> 86%) of palladium

- Cost-effective at ≤ USD 2.12/L extracting up to 4,000 ppm palladium at saturation within 12 hours

- Easy adoption and high compatibility with existing industrial hydrometallurgy systems

- Improve workplace safety and health which better protects workers and the environment

POTENTIAL APPLICATIONS

- Electronic wastes, such as Pd-coated connectors, Pd-coated wire bonding, etc.

- Pd-coated industrial wastes

- Recovered palladium can be further refined for resale and reuse

Market Trends & Opportunities

In recent years, many countries have mandated environmental responsibilities to electronic manufacturers to establish producer recycling programs and ban E-waste disposal into landfills. E-waste contains precious metals, such as palladium, gold and silver that are highly sought-after by E-waste recycling companies due to their scarcity, high value and demand, and are actively traded as commodities over the last decades. The extraction of precious metals from E-waste is not only commercially attractive but also aligns with Corporate Social Responsibility and Environmental, Social, and Governance goals for resource recovery and environmental protection.

The global E-waste market size was valued at USD 52.6 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 12.1% from 2022 to 2032, to reach USD 160.2 billion (Market.us, 2023).

Unique Value Proposition

The proposed technology features a proprietary lixiviant capable of extracting palladium up to 4,000 ppm at saturation with a high extraction efficiency (≥ 89%) and high purity (≥ 92%). This cost-effective lixiviant is significantly less hazardous as compared to current industrial practices, thus better protecting workplace safety and health. Notably, the technology is compatible with existing hydrometallurgy processes and has been successfully verified at pilot-scale (5-Litre) in collaborating with an industry partner.