Maximising Cell Cultivation With Low Cost 3D Scaffolding

KEY INFORMATION

Foods - Ingredients

TECHNOLOGY OVERVIEW

The current clean meat technologies grow lab meat with conventional 2D cell culture. However, the conventional cell culture technique has an overall low yield of cells, as the cells are restricted to growth on surface areas.

A new 3D scaffolding method has been developed to overcome this problem with the use of microcarrier beads that provide cells with additional surface area to attach onto and proliferate. The microcarrier beads are suspended in the cell culture thus maximizing the 3D volume of the cell culture, leading to an increased yield. A microcarrier type has been identified to yield the highest number of porcine cells. The conditions of the cell culturing process have been optimised to improve the cell viability in a 3D environment

Companies interested in cell-cultured meat development could consider using this method to grow cell-cultured meat at a larger scale with a potentially lower cost of production. The technology developer is seeking companies that are keen to scale up lab-grown meat applications.

TECHNOLOGY FEATURES & SPECIFICATIONS

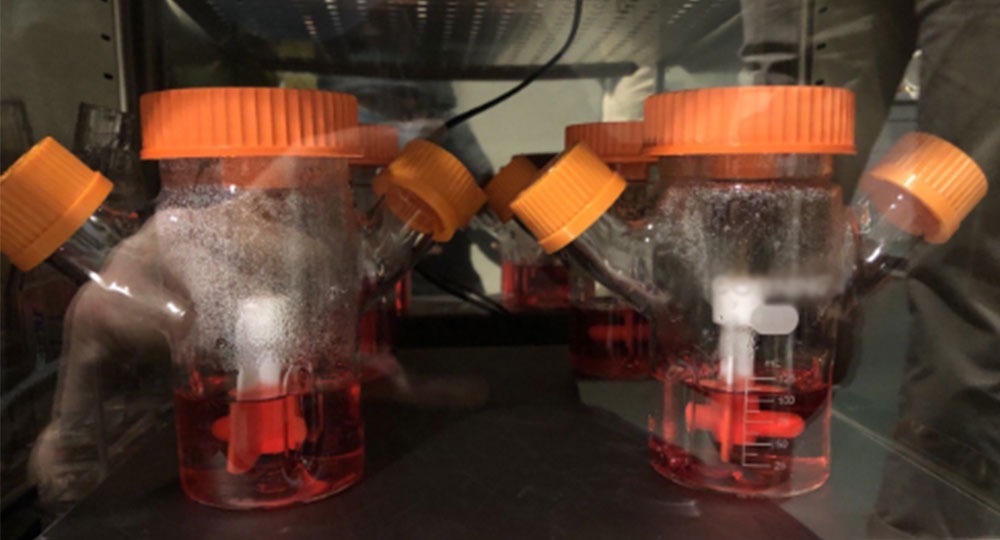

The technology owner uses microcarrier beads, which are small (approx. 75 um diameter) polymer beads. They collectively provide a significantly larger surface area than standard tissue culture flasks for cell growth. Typically used in the pharmaceutical industry to scale up cells for protein expression, the use of microcarrier beads for the scale-up of cell-cultured meat is a relatively new application.

Some key features of the technology:

- Increases cell yield by 7-fold from lab-scale

- Microcarrier beads hold their shape throughout

- Made up of inert and food grade material

- Different cell types require specific types of microcarrier beads to optimize growth

POTENTIAL APPLICATIONS

The method is suitable for:

- Clean meat industry / Cultured meat companies

- Pharmaceutical companies that apply such technologies towards protein manufacturing, drug discovery or antibody production.

- Other potential clean meat applications using other cell line sources.

Market Trends & Opportunities

With the increasing demand for meat production for population consumption, there is a need to look at other more sustainable meat source. Lab grown ‘clean meat’ can be an alternative to livestock farming. The development of ‘clean-meat’ can help to reduce carbon footprint, improve animal welfare and prevent foodborne illnesses. The cultured meat market size was valued at $1.6 million in 2021 and is projected to reach $27 billion by 20301.

1Cultured meat market size, share - global industry report, 2022-2030. Allied Market Research. April 2021.

Unique Value Proposition

- Increased yield of viable cells as compared to 2D cell culture

- Scalable

- Up to 7x lower in cost of production at a larger scale

- Pathogen-free source of meat produced

- High reproducibility

- Low usage of microcarrier beads: 10g microcarriers/20 litres of cell culture