Veteran dried bee hoon producers, People Bee Hoon partners with RoPlus to fuse technology in producing the traditional bee hoon.

Bee hoon or rice vermicelli, is a well-loved staple ingredient across Southeast Asia. From Singapore's satay bee hoon to Malaysia’s bee hoon goreng—these noodles warm up family dinners and breathe life into numerous Asian dishes.

Founded in 1943 under its flagship ‘Chilli’ brand, People Bee Hoon Factory products have been a mainstay in pantries across Singapore. The company manufactures dried rice vermicelli from rice grains sourced from Thailand to be used by homecooks, restaurants, food courts and many others. In an effort to introduce bee hoon dishes to more families within and beyond Asia, People Bee Hoon’s methods have evolved from labour-intensive, handmade processes to semi-automated production, all while maintaining a distinctive taste and fragrance.

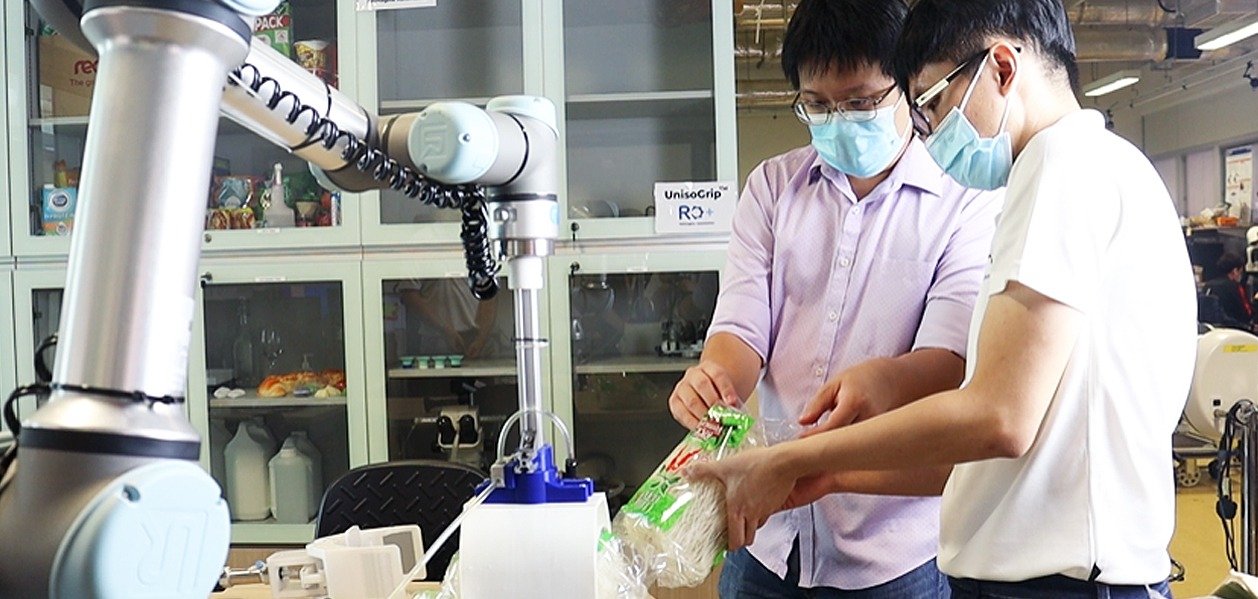

However, the delicate nature of bee hoon meant that some processes still required manual labour. This has further intrigued the People Bee Hoon to explore new machinery and technology to automate production to ensure consistency and quality of the products. With IPI’s help, People Bee Hoon partnered with RoPlus, a smart automation solutions provider equipped with soft robotic gripper technologies.

People Bee Hoon faced two production bottlenecks: folding the bee hoon and the secondary packaging process. The latter involves manually transferring the dried bee hoon bags to plastic bags or carton boxes. As the company began exporting in 2011, production capacity had to be increased.

“At first, we relied on hiring more staff to keep up with the demand. However, doing this proved to be unsustainable and was not increasing our capacity fast enough,” shared People Bee Hoon Factory Director, Desmond Goh.

The company explored various automation solutions offered by robot arm original equipment manufacturers but the irregular sizes of the packs and the fragile nature of the bee hoon proved to be an obstacle.

In May 2021, People Bee Hoon sought out RoPlus’ reconfigurable hybrid robotic gripper technology through IPI’s Innovation Marketplace, which offers a list of curated enabling technologies. As a spin-off under the National University of Singapore’s Graduate Research Innovation Programme, Roplus is commercialising soft robotic gripper technologies for food and fast-moving consumer goods production use.

“Traditional rigid grippers struggle to work with delicate food items like tofu and pudding. These grippers usually consist of fixed gripper bases, which also limit its ability to grip a diverse range of items,” said RoPlus Chief Marketing Officer Han Qian Qian

To accommodate a wide range of products, RoPlus’ soft robotic grippers incorporate pneumatic pressure sensors and programmable rigidity of finger segment technology to handle delicate items of various shapes and sizes.

For People Bee Hoon, the versatility of RoPlus’ gripping solutions perfectly complements the bee hoon’s meticulous production process. During its engagement with People Bee Hoon, RoPlus customised automated solutions for the two production bottlenecks of the factory.

By closely observing how human workers fold the bee hoon, RoPlus designed a wet bee hoon folding machine that mimics the folding motion, making the folding more consistent and less labour-intensive.

“We managed to save around 1,300 man hours per month. The machine made the folding less physically exhaustive and allowed us to place older workers in the department and redeploy excess manpower,” said Goh.

In the next phase, the teams will look into the secondary packaging project. To automate the secondary packaging process without damaging the delicate bee hoon packs, RoPlus designed a gripper that grips the bee hoon at its four corners. “It was almost impossible to squeeze grippers between the packed bee hoon and the box without damaging the product,” shared Qian Qian.

Both companies recognise the role IPI played to their mutual success. Goh says that People Bee Hoon remains on the lookout for further collaborators introduced by IPI to modernise its business. For RoPlus, IPI’s platform allowed them to testbed their technology and get a step closer to commercialising their solutions.

“IPI’s tech matching is very beneficial for start-up companies or SMEs like us because it not only helps us find potential partners, it also brings in clients who would like to explore our technologies,” shared Qian Qian.