Automation for Safety and Productivity in ManufacturingLearn more about three new robot technologies that can revolutionise our future industries

One of the first industries to embrace automation, manufacturing remains on the leading edge of adopting robot technology. Think, for example, of the automotive industry’s move from the assembly line to the heavy use of robotics in the last century. Manufacturing has pushed engineering innovations into the field, as robots increase efficiency, precision and safety, as well as decrease operating errors and costs.

Robot technology can also free workers from laborious, mundane and hazardous tasks. Safety through automation has become even more crucial in the age of COVID-19, where a virus rapidly became an invisible threat to our work environments. The pandemic certainly accelerated the adoption of robot technology, which in turn can transform our post-crisis industries in ways we have yet to imagine.

In this article, we highlight three emerging automation technologies that can make our workspaces safer and more productive, without sacrificing the health and safety of the workforce.

Automation Made Accessible

Automation Made Accessible

In the age of “smart factories” where operations are digitally connected and highly automated, a diverse range of robots are already used for a variety of tasks, working alongside humans to increase productivity. Robots have been deployed in some workspaces that are hazardous to humans, such as in places where there is an increased risk of exposure to toxic substances. However, such technologies may not be readily accessible to small and medium enterprises (SMEs) or users without robotics expertise.

A cost-effective and customisable autonomous transporter seeks to fill this gap. This wheeled robot, controllable with a Wi-Fi enabled joystick, is built on the open-source Robot Operating System. Its configurable chassis caters to additional equipment such as GPS systems or a variety of end-effectors. This means the transporter can be readily customisable for the end-user—even with little hardware or software know-how—to achieve a multitude of tasks that meet the specific needs of their business.

The autonomous transporter can be deployed in medical facilities, warehouses, and even as digital tour guides. The cost of development for the robot is relatively low, making it accessible to SMEs, as well as to researchers who wish to build on this existing platform.

When Robots Lend a Hand

When Robots Lend a Hand

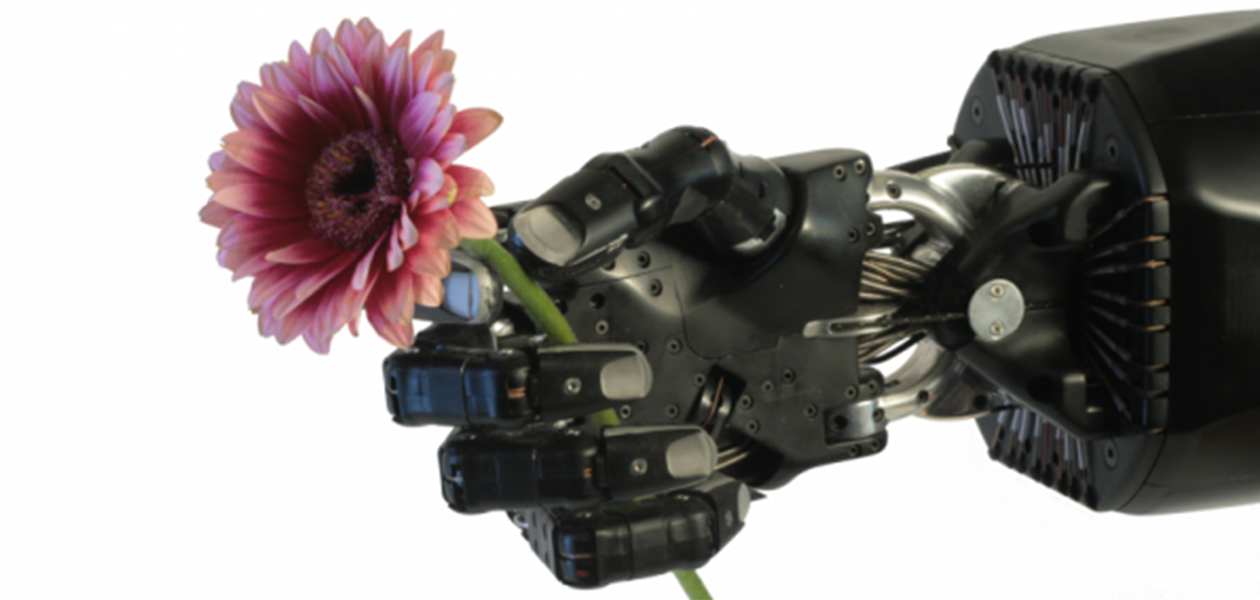

While robots have steadily become more human-like, their upper limbs usually end in crab-like pincers that may not have the fine motor skills of the human hand. This means that high-risk tasks requiring high dexterity and manipulation, like the handling of chemicals and defusing a bomb, are still dependent on humans.

To address this issue, a new robot hand has been developed to be anthropomorphic, smart and adaptable. With ultra-sensitive touch sensors on its fingertips, the human-sized robot hand is able to sense force, temperature, motor current and voltage. Furthermore, its 24 joints allows for 20 actuated degrees of freedom, enabling it to closely replicate a human hand’s range of motions.

The dexterous robot hand, which can also be mounted on a range of robot arms and seamlessly connect to an existing robot system, could potentially replicate human movements during hazardous and potentially life-threatening activities, such as nuclear decommissioning, bomb disposal and handling of hazardous chemicals.

Leaving Ardous Work to the Drones

Leaving Ardous Work to the Drones

Another aim of automation is to free up human workers from routine tasks for higher-level ones, and at the same time increase workplace efficiency. Examples of routine but important tasks include cycle counting in inventory management, or the periodic auditing of stock kept in a warehouse. Such tasks that might typically take anywhere from two to eight hours to be completed, could be achieved within a mere 15 minutes using an autonomous drone designed for use in warehouses.

The fully autonomous drone is fitted with an on-board camera and utilises automatic identification processes including QR (quick response) codes and RFID (radio frequency identification). It is perfect for inventory management as it can ensure 100% accuracy in scanning items and logging data in real-time.

The drone is also designed to be a plug-and-play solution, with set-up taking only 30 minutes. Instead of an operator on a scissor lift scanning items one by one, multiple drones could zip through—and up and down—the warehouse aisles. The operator can then be re-assigned to higher-level, non-routine tasks, such as analysing the data collected by the drones.