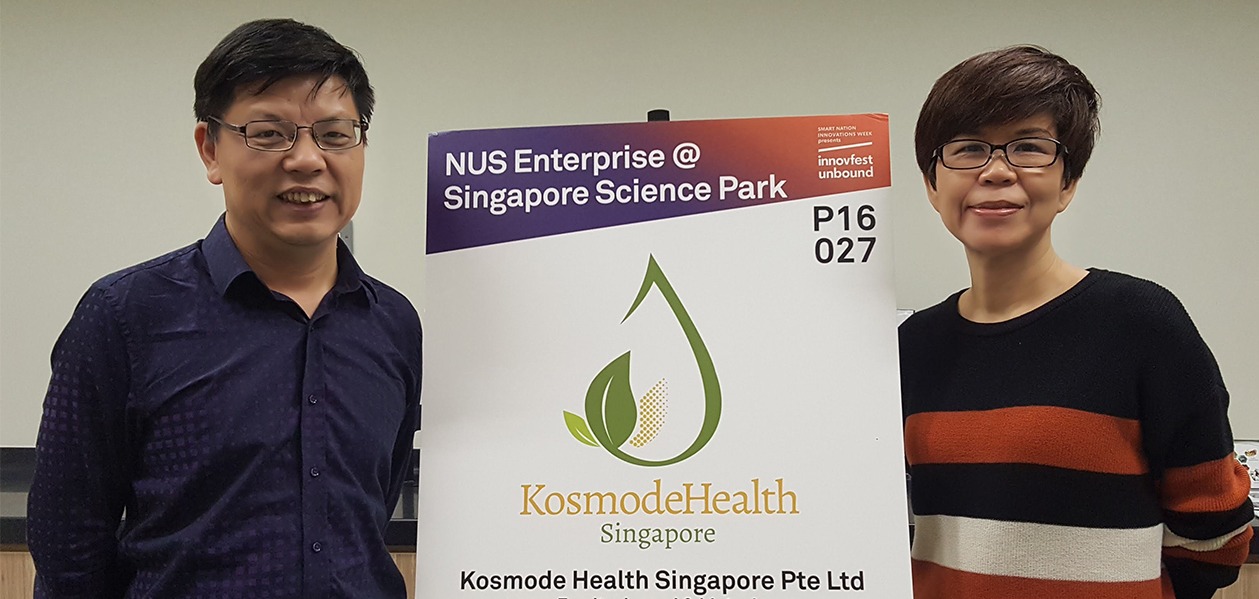

Extracting value from food wasteWith nature as their north star, Singapore-based food technology startup KosmodeHealth is finding plant-based solutions for the agri-food and biomedical industries.It is estimated that a third of all the food grown for consumption ends up going to waste. This wastage largely stems from the disposal of by-products generated by food processing, such as the barley grains that are no longer used after brewing beer. These by-products are actually high in protein and fibre but are currently mainly ‘up-cycled’ into animal feed and fertilisers. With the right processes, these proteins and fibres can be efficiently recovered and formulated into functional products for human consumption.In a world where sustainability and food security are fast becoming crucial priorities, technology that can extract the maximum value from food by-products is more important than ever. One such company hoping to achieve this is food technology start-up KosmodeHealth, led by co-founders Florence Leong and Professor Huang Dejian. Combining Leong’s entrepreneurial instincts and Huang’s scientific expertise, the duo established KosmodeHealth in 2016 with the mission to reduce food by-product wastage and make high-quality plant-derivatives more affordable to consumers.In an interview with IPI, Leong discusses KosmodeHealth’s story since its inception and the company’s collaborative approach to solving the challenges faced by agri-food and biomedical companies today.

1. What inspired you to set up KosmodeHealth?

KosmodeHealth Singapore originated from an almost two-year mentor-mentee relationship between myself and Professor Huang Dejian of the National University of Singapore, who was amongst my first few mentees.

I am a firm believer that quality health products should not be the exclusive privilege of those with deep pockets. Dejian’s research has enabled us to efficiently and sustainably extract high-purity plant extracts, as well as reclaim proteins and fibre from food processing waste, which are now given the more acceptable terms of ‘by-products’ and ‘side stream’ respectively.

Both of us share a common mission to expand access to health through natural sources. Nature has endowed mankind with health-giving materials, so why should high-quality functional products formulated from plants be more expensive than synthetic, chemically-derived products?

2. What are the real-world challenges that KosmodeHealth is trying to address?

We aim to reduce the cost of extracting high-value products in agri-food industries. Current bioactive extraction methods require large land space, expensive capital equipment and high energy consumption due to repeated rounds of distillation for increased purity. High cost extraction, coupled with the extremely low content of health-giving bioactives in fruits and plants—often less than 0.1%—are why quality plant-based products are expensive, thus limiting their mass-market affordability.

Whilst the bioactives content in fruits and botanicals are extremely low, the protein and fibre content in food-processing ‘waste’—such as spent barley grains after brewing beer, spent coffee and spent canola meal—are extremely high. These ‘waste’ or side streams have high fibre and protein levels of up to 50%. They are currently dried at extensive energy costs into animal feed and fertiliser. It is time to ‘wrestle’ these proteins and fibre into products for human nutrition.

We have also used recovered plant proteins as a 3D bioscaffold for the biomedical industry. Our Plant Protein Composite (PPCTM) 3D bioscaffold addresses the high costs and issues associated with the use of animal proteins in cell culture, as well as the deficiencies of commercially available 3D bioscaffolds in meeting the growth requirements of diverse cell types.

3. What made KosmodeHealth decide to explore open innovation, despite the company being a fairly young SME?

People have often asked us, “How does a startup with core expertise in extraction impact the biomedical industry?”

This is how it all began: Dejian bumped into another professor along the corridor at the National University of Singapore (Suzhou) Research Institute. This professor shared about her proprietary 3D printing technology that can precisely print 3D bioscaffolds in different shapes and sizes, even at the sub-micron level. However, she also lamented that there was no bio-ink suitable for cell growth that could be printed in such fine structures without breaking. As we happened to have just extracted some proteins from corn spent grains, Dejian offered to try formulating some bio-ink with the corn protein, called zein. It was this conversation that led to KosmodeHealth’s innovation: the world’s only PPCTM 3D bioscaffold. This incident reflects the importance of openness, networks and the willingness to explore, all key ingredients for success in the innovation ecosystem.

4. How has open innovation benefitted KosmodeHealth, and how do you encourage a culture of open innovation within the company?

KosmodeHealth was incorporated to be a business enabler. We use our proprietary plant extraction expertise and plant protein composite 3D bioscaffold printing technologies to support functional food development from up-cycled materials and 3D cell culture in the food and biomedical industries respectively.

Open innovation and co-creation are in our DNA. They have helped us achieve market traction; many of our early clients are connections referred to us by partners such as IPI, Enterprise Singapore, A*STAR, etc.

Open innovation is especially important for novel applications such as our PPCTM bioscaffold. As a novel platform, collaborations with fellow researchers in tissue engineering, regenerative medicine and drug discovery are extremely important for creating new use cases. We are currently collaborating with researchers in Singapore and Malaysia by providing our novel PPCTM bioscaffold for their cell culture needs. We are also open to customising 3D bioscaffolds for our research partners.

5. How can open innovation make a difference to local SMEs, particularly those in the food and biomedical industry, during these uncertain times?

I firmly believe that Singapore’s innovations can only thrive when Singapore enterprises join hands, complement each other and not be ‘kiasu’. As the saying goes, “United we stand, divided we fall.” This is especially so in today’s fluid, dynamic and complex environment.

KosmodeHealth’s progress is built on the shoulders of ‘big brothers’ such as RedDot BrewHouse and KH Roberts Pte Ltd. RedDot’s support with the provision of spent barley grains has enabled us to optimise our protein and fibre extraction process, whilst we would not have been able to demonstrate the scalability of our extraction process without the pilot-scale facility provided by KH Roberts.

Their support enabled us to create what I believe to be the first Protein Fibre Starchless (PF0S) noodles. The PF0S noodles are specially formulated to address blood sugar and weight issues. As a starchless noodle, it enables the consumption of an Asian staple without the associated blood sugar concerns. At the same time, the noodles provide six grams of protein and 16 grams of fibre per 100 gram serving. We believe our PF0S noodles could go a long way in helping to manage the high prevalence of diabetes in Singapore

Currently, spent barley grains processed in large generators are only qualified for use as animal feed or fertiliser. We hope to see the relevant government agencies drive the collection of food-grade spent grain so that the protein and fibre from the almost 80,000 tonnes of spent barley grains generated each year can be reclaimed for functional food production.

We estimate that the protein and fibre reclaimed from spent barley grains will enable the production of more than 150 million servings of PF0S noodles every year. This will not only contribute to achieving the 30 by 30 food sustainability goal but also help meet the recommended dietary allowance of protein and fibre for more than 100,000 Singaporeans.