Plug & Play AI Module for Manufacturing Efficiency

KEY INFORMATION

Manufacturing - Assembly, Automation & Robotics

TECHNOLOGY OVERVIEW

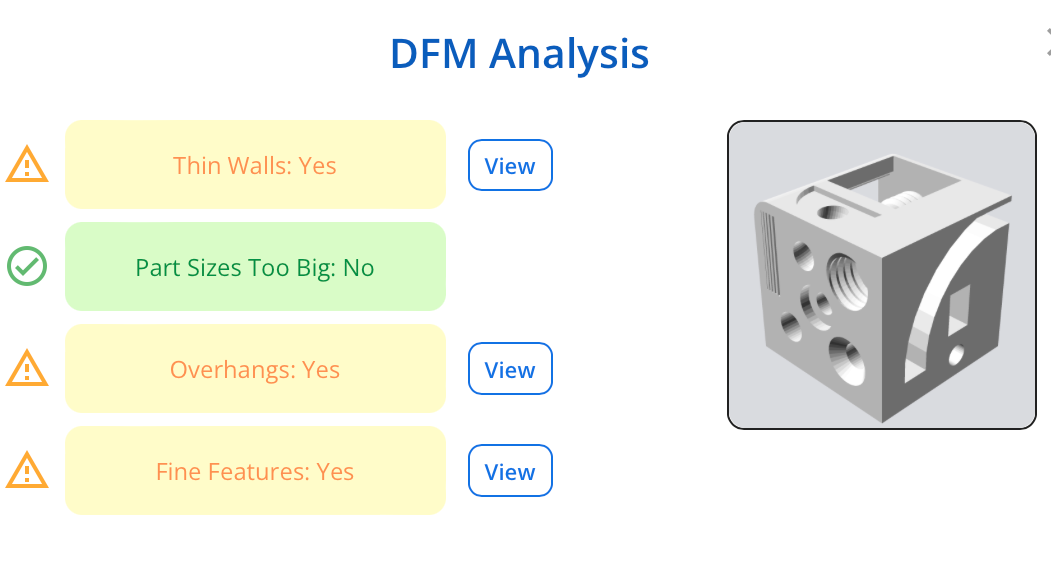

Traditionally, Design for Manufacturing (DFM) feedback is provided late in the product development cycle, often resulting in costly redesigns, production delays, and missed opportunities for optimization. This invention introduces an AI-powered companion that delivers real-time DFM feedback early in the design and demand fulfillment process. By automatically analyzing CAD models and design parameters, it identifies features that may pose manufacturing challenges and offers actionable suggestions to improve feasibility and reduce costs. The AI companion empowers users to make informed design decisions without waiting for manual reviews or relying solely on in-house manufacturing experts.

In additional, traditional quoting methods are labor intensive and inaccurate, requiring engineers to analyze technical drawings, assess material and process requirements, and estimate costs based on historical data or supplier inputs. This delays customer responses and increases operational overhead. The proposed technology leverages AI to automatically interpret design files (e.g., CAD or technical drawings), extract key manufacturing features, and generate instant, data driven price estimates.

The technology owner is seeking collaborators in tailoring this AI module to specific industries, applications, and business processes. Target users include precision engineering firms, job shops and manufacturers. The solution can enable businesses to respond faster to customer inquiries, reduce quoting costs, reduce design for manufacturing leadtime and win more business.

TECHNOLOGY FEATURES & SPECIFICATIONS

- AI Companion for DfM Validation: User will load in CAD or drawing. Solution will be based on unique requirements and manufacturing capabilities of customers. It calls out design constrains and offers actionable suggestions to improve feasibility and reduce costs.

- Automated Instant Pricing for Manufacturing: User will load in CAD or drawing and manufacturing process. Solution will project an estimated quotation with use cases at >80% accuracy. The AI engine calculates pricing by factoring in labor, material costs, machine time, overhead, and historical quotation data to ensure accurate and consistent estimates. Quotation can include estimated raw material cost, cost price and selling price.

- Flexible and Integrated Deployment: Used as a plug-in API as part of a larger internal tool, or a standalone solution with a simple UI developed for customer to upload and view design feedback. A web-based user interface and API allow users to upload design files, receive instant quotes, and seamlessly integrate the system into existing ERP, MRP, or e-commerce platforms.

- AI Powered: Technology consists of a combination of software algorithms, machine learning models, and integration tools. Supporting this is a robust database that stores material pricing, manufacturing parameters, and user interaction data, enabling continuous model learning and optimization over time.

- Scalable Implementation with Additional Features: DfM Validation and Instant Pricing solutions can be part of a plug-and-play AI module that cover 50 features across operation efficiency such as production job tracking and inventory management.

POTENTIAL APPLICATIONS

Target users include precision engineering firms, job shops, manufacturers, online marketplace and any product owners. This includes users employing different manufacturing processes such as CNC machining, 3D printing, and sheet metal fabrication.

Solution is applicable across different industries including consumer, defense, aerospace and semiconductors. It is especially valuable in industries where rapid prototyping, custom part production, or low-volume manufacturing are common to achieve goals below:

- Real-time DFM feedback early in the design and demand fulfillment process to reduce number of design iterations required, shortens development timelines.

- Real-time manufacturability and cost feedback during the design phase.

- Backend engine for procurement automation, enabling sourcing teams to quickly benchmark and compare supplier quotes.

Market Trends & Opportunities

The Computer-Aided Manufacturing (CAM) Market is expected to increase from $3.39 billion in 2024 to $5.69 billion by 2030, at a CAGR of 9.0%. This reflects big growth in the manufacturing sector. With so much to manufacture and design, it becomes even more pressing to create more efficient workflows, develop shorter design iteration cycles and get feedback in real time. In addition, the global manufacturing industry is a substantial and growing sector, valued at approximately USD 14.16 trillion in 2024 and projected to reach USD 20.76 trillion by 2031, with a compound annual growth rate (CAGR) of 4.9%. Within this vast landscape, the High-Mix, Low-Volume (HMLV) segment is emerging as a critical area of growth, driven by increasing demand for customisation, rapid prototyping, and shorter product life cycles across industries such as aerospace, medical devices, and electronics. Despite its strategic importance, the HMLV segment remains largely underserved, particularly in the area of pricing automation. Most job shops and small-batch manufacturers still rely on time-consuming, manual quoting processes for each unique part or drawing. This creates a significant bottleneck, limiting responsiveness, efficiency, and scalability.

This solution stands out from similar technologies in the market because of the solutions providers strong record in servicing diverse clients. This tool has been verified and trained on real world design files from a variety of clients from different industries and has become a key portion of our optimised workflow. It is customised to customer's problem statement, supporting unique and niche designs for specific markets. The solution offers a powerful combination of CAD feature recognition, AI-driven cost estimation, and seamless ERP/API integration to automate pricing at speed and scale. Unlike existing tools like basic quoting templates, this system intelligently learns from historical data and adapts to new designs, delivering both accuracy and agility.

Unique Value Proposition

- Reduction in number of design iterations: Shortens development timelines, and supports the creation of more practical, production-ready designs.

- Significant reduction in turnaround time for quotation: Replaces traditional quoting methods are labor intensive and inaccurate, requiring engineers to analyze technical drawings, assess material and process requirements. Shorten quotation timeline from a few days to few seconds.

- Auotmates workflow that typically requires profession: Provides analysis of CAD/drawings which is particularly beneficial for product design teams, manufacturing engineers, and procurement professionals who play a role in assessing manufacturability and sourcing.

For small and mid-sized manufacturers, this can lead to a higher quote win rate and better customer service. For larger enterprises, it supports scalability across multiple product lines or factories.