Autonomous Vision Inspection for Manufacturing

KEY INFORMATION

Infocomm - Video/Image Analysis & Computer Vision

TECHNOLOGY OVERVIEW

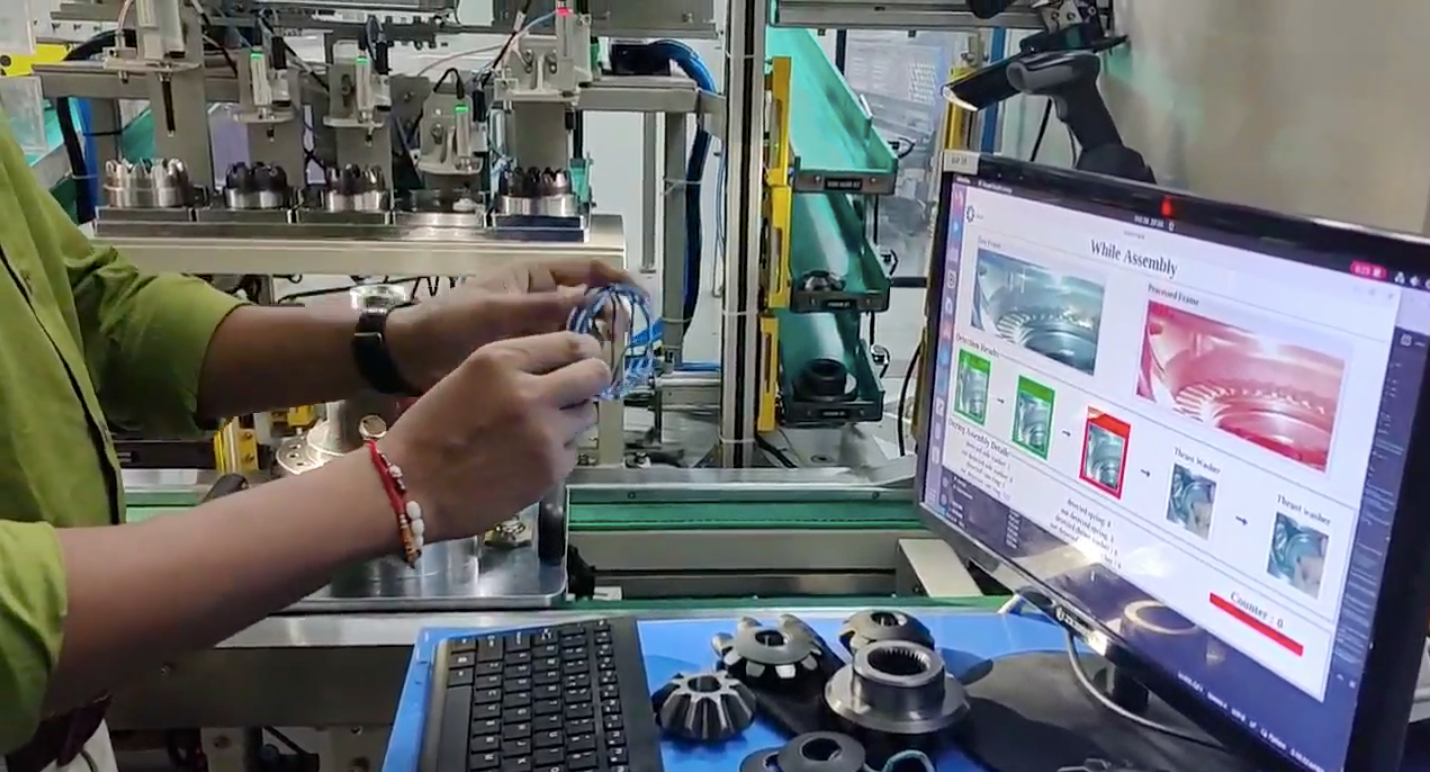

In manufacturing, critical end-of-line inspections often remain manual due to the rigidity of traditional machine vision solutions. Although various inspection solutions have been developed over the years, widespread adoption has been hindered by implementation challenges, lengthy model training times, and high costs. For manufacturers dealing with rapidly evolving products, legacy purpose-built systems become harder to maintain. For them it is advantageous to invest in a manual process and team that can adapt and innovate throughout their product lifecycle. However, this approach is restrictive since manual quality checks performed have 15-20% undetected errors due to human error and oversight.

The technology owner has leveraged on AI-powered workflows and advancement in process intelligence to develop a vision-based inspection technology solution for autonomous quality checks. This solution surpasses traditional solution rule-based system by being able to have the ability to learn features from surface and flag instances of deviation while allowing easy modification by non-expert personnel to accommodate any product changes. The AI capabilities enable faster training with fewer datasets to train models and detect errors effectively while enabling identification of individual products and prediction of component-specific errors. In addition, this technology solution provides multitasking and 3D inspection capabilities, allowing more than one type of concurrent inspection and catering for larger and complex geometry objects.

The technology owner has previously conducted successful quality assurance pilot tests within the automobile, precision engineering, defence and FMCG industries. The owner is currently seeking collaboration partners to empower manufacturers to maintain high-quality standards while keeping pace with rapid product evolution, ultimately reducing costs and improving overall production outcomes.

TECHNOLOGY FEATURES & SPECIFICATIONS

The vision-based inspection technology solution for autonomous quality checks harnesses the power of computer vision, artificial intelligence, and machine learning for the following specifications:

1. Proprietary Deep Learning AI Algorithms: The technology solution employs multimodal AI algorithms such as convolutional neural networks (CNNs) and other sophisticated deep learning models, in conjunction with natural language processing (NLP) and autonomous machine vision (AMV). These proprietary AI models are meticulously trained on extensive datasets and integrated seamlessly, providing increased accuracy, reliability and self-serving capabilities.

2. Advanced Synthetic Data Generation: Leveraging the power of state-of-the-art AI generative models, it enables the creation and utilisation of diverse and high-quality datasets that shortens the training process while maintaining its deployment efficiency.

3. Custom Software Solutions: The proprietary software enables segregation of capabilities (e.g. OCR, image processing, real-time data analysis) for customisation and integration to other systems, like MES and ERP, for value-added capabilities other than defect detection, ensuring seamless operation across diverse applications while delivering comprehensive and user-friendly experiences.

4. Microservice Architecture: The distributed microservices within the technology solution provides flexibility in scaling and adapting the software to multiple workflows and inspections.

In addition to the above capabilities, the technology solution enables the following:

- Customisable and adaptable to product change and region of interest for quality assurance checks

- Ease of scalability catering to difference sizes of production and manufacturing line

- Hardware and product agnostic

- Fast deployment (up to 6 weeks) with shortened training downtime

- Enables non-expertise personnel to train and redeploy technology solution

- Build report dashboards and triggers for improving workflow process and overview

- Data driven insights for value-add operational performance

POTENTIAL APPLICATIONS

The technology solution is designed to replace manual inspection processes by providing an efficient and accurate automated inspection capabilities across various applications, including:

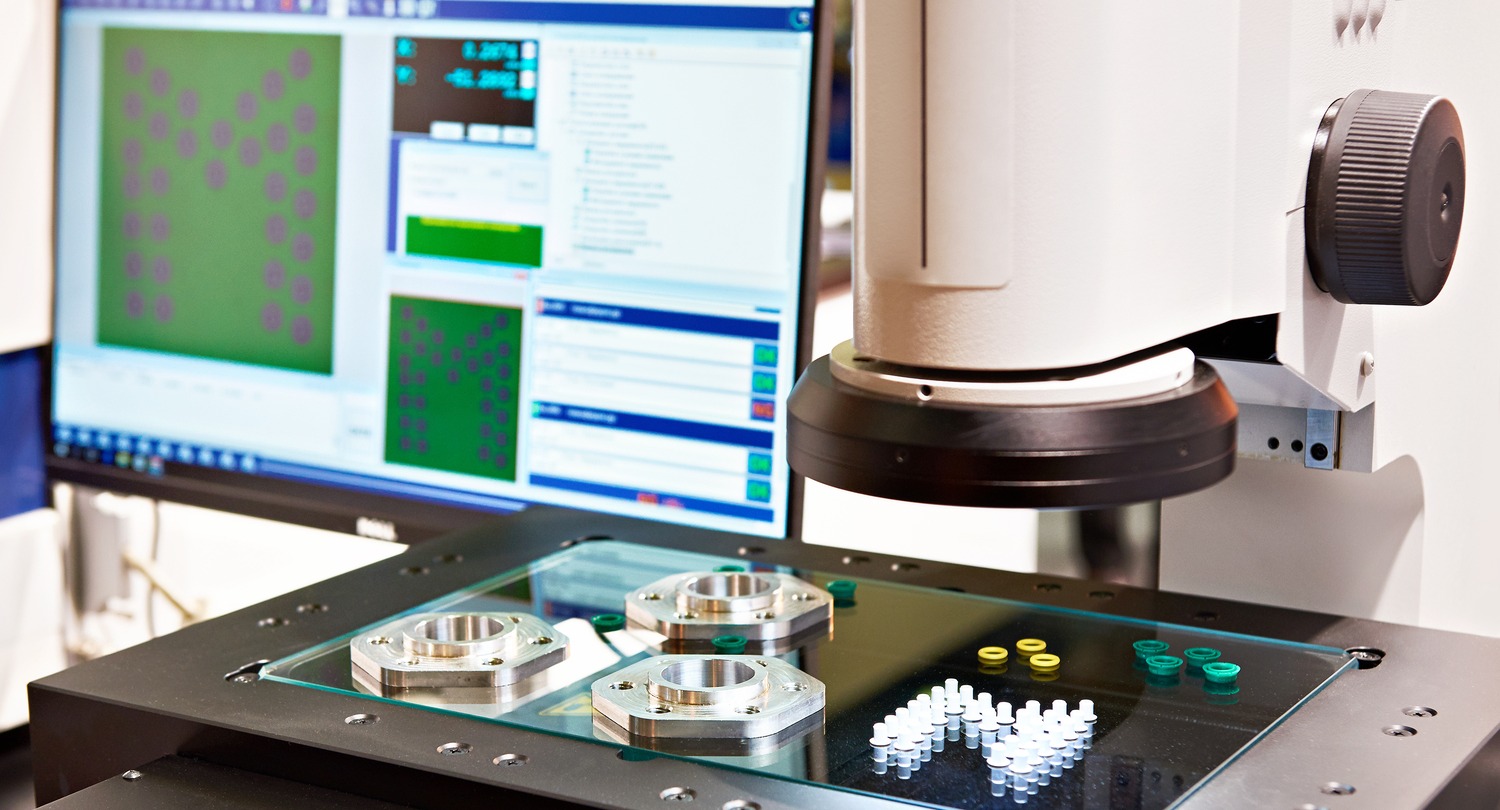

1. Surface Inspection: Detecting cracks, dents, scratches, and other surface defects on components.

2. Presence/Absence of Features: Verifying the presence or absence and counting the number of features on a component.

3. Gauging: Measuring dimensions such as sides and angles with high precision.

4. Object Recognition / Pattern Detection: Identifying and indexing objects and its inconsistencies, design flaws, and discoloration respectively.

5. Pipe Inspection: Assessing weld quality and detecting cracks and dents inside pipes.

6. OCR/Scan Codes: Scanning and reading information etched on surfaces or encoded in barcodes and QR codes.

7. Efficiency and Quality Calculation: Evaluating quality of production batches while analysing shift and operator efficiency.

8. 3D Inspection: Leveraging on point cloud capabilities for inspecting large body such as in aerospace

Market Trends & Opportunities

The global machine vision market was valued at $52B billion in 2021 and is expected to grow at a CAGR of 11.3% from 2022 to 2027.

Unique Value Proposition

The autonomous machine vision platform is designed for defect detection by replacing manual inspection with AI-powered, hardware agnostic modules, enabling compatibility across various existing hardware setup. The technology solution offers versatile and customisable defect inspection capabilities for any dynamic inspection process. Leveraging on proprietary GenAI, minimal training data (30-50 images) is required for the solution to be deployed within six weeks, lowering implementation barriers while maintaining precision. The product agnostic capability enables seamless updates for product changes while enabling non-technical expertise to operate and manage, lowering operational cost. By leveraging on data driven insights generated, better and more informed production decisions can be made, improving production efficiency.