Boron Nitride Composites For Thermal Management

KEY INFORMATION

Materials - Composites

TECHNOLOGY OVERVIEW

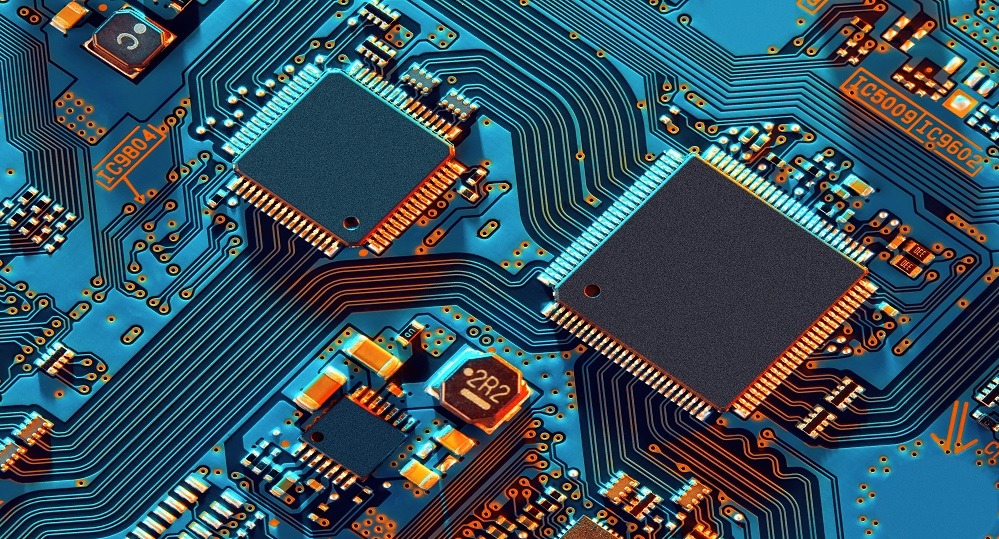

Thermal management is an essential part of the design of high power density electronics. As the power density of electronic devices increases, so does the amount of heat they generate, and this heat must be dissipated effectively to prevent the devices from overheating and failing. This technology offers a method to produce high thermal conductivity boron nitride (BN) composites that aim to improve thermal management in high power density electronics, leading to more efficient, more compact, and safer electronic systems.

BN composites are a group of materials made by combining boron nitride with another material, such as a polymer, metal, or ceramic. A key advantage of such composites is that they exhibit higher thermal conductivity than any commercially available material that is electrically insulating. The resultant BN composites are also low in weight, easily shaped, exhibit good mechanical properties, and offer the unique capability of designing the path by which the heat will be conducted. These properties fulfil the demanding requirements for electronic packaging in emerging markets like Internet of Things and embedded systems, autonomous vehicles, high speed computers, satellites to name a few.

The technology owner is seeking for co-development and out-licensing opportunities with semiconductor and device-assembling companies that require high thermal conductivity materials.

TECHNOLOGY FEATURES & SPECIFICATIONS

This technology consists of a method to fabricate porous boron nitride composites that exhibit high thermal conductivity for improved heat management. Using a simple and scalable process, BN microcrystal powder is functionalised with iron oxide nanoparticles. BN microplatelets are then orientated to channel heat along the direction of alignment of the microplatelets to yield BN composites of high thermal conductivity.

Some features of the BN composites include:

- Utilises a green process to fabricate (water is used as a solvent)

- Exhibits higher thermal conductivity (12 W/mK)

- Lightweight (~1.3 g/cm3)

- Good mechanical properties (Stiffness ~400 MPa, strength ~3 MPa, hardness 0.5-1.5 kgf/mm2)

- Electrical resistivity (~30 MΩ.cm)

- Tunable shape and size

- Excellent thermal stability till 200 ºC

POTENTIAL APPLICATIONS

The BN composites can be attached to electronic chips and other components, making them suitable as a thermal interface material for 3D electronics of high packing density.

Possible applications include (but are not limited to):

- Semiconductor

- Aerospace

- Automotive

Unique Value Proposition

- Higher thermal conductivity than conventional thermal interface materials with electrical insulation

- Ability to customise and tailor the BN composites’ properties to efficiently channel heat into specific directions