Cost Effective Benchtop Powder-Free Metal Hybrid Manufacturing System

KEY INFORMATION

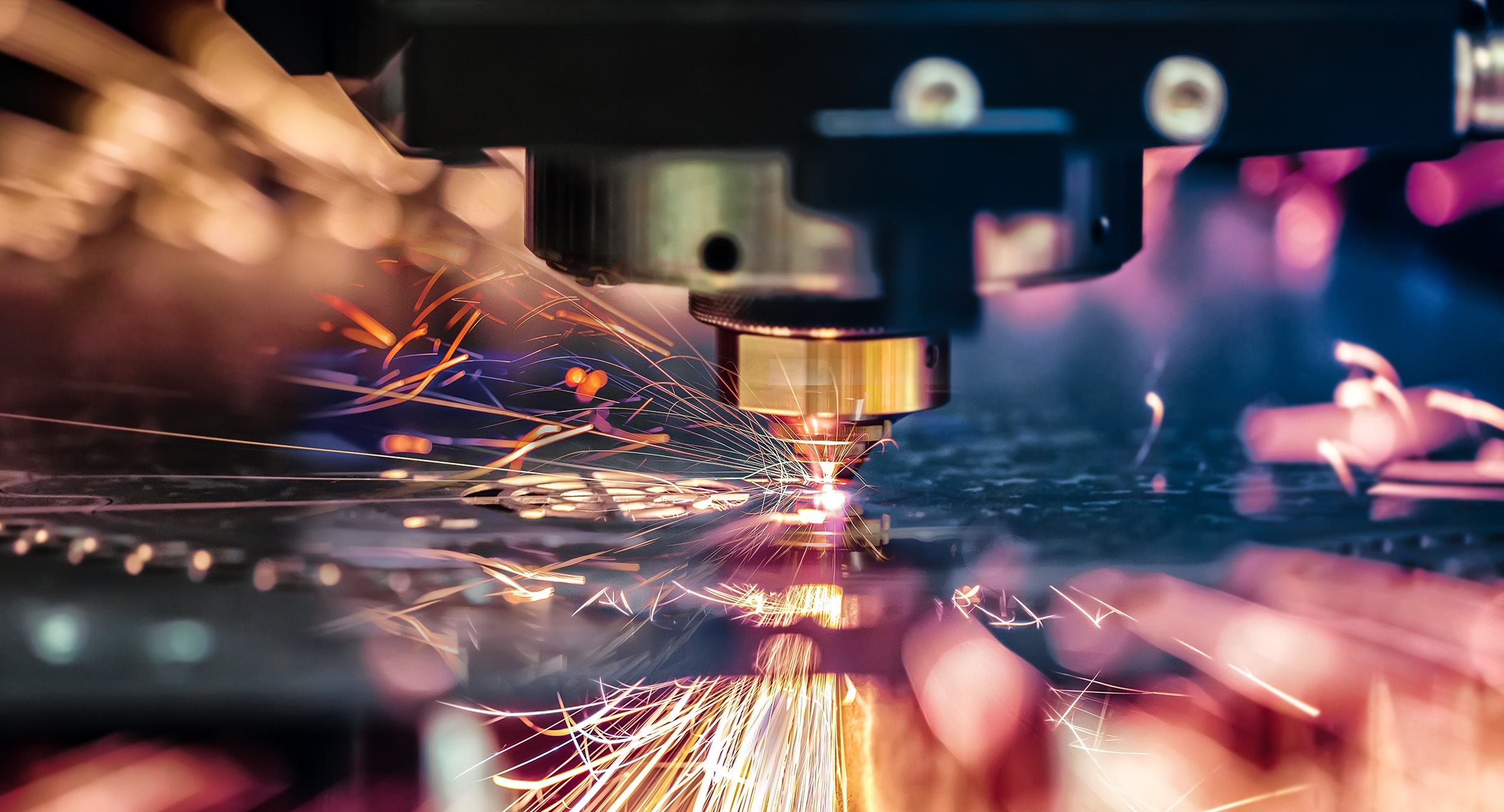

Manufacturing - Subtractive Machining

TECHNOLOGY OVERVIEW

In manufacturing there are many instances where there is a need for low production runs of parts. These could be for parts of an equipment, tools, small volume runs for trials or customised parts. However, traditional manufacturing techniques are usually not cost-effective for such low volume runs, while current additive manufacturing suffers from low strength, long print times and poor surface finish needing post-processing. Additionally, for techniques using powder and filaments, considerations have to be given to the storage and operational set-up due to oxidation, degradation, flammability and toxicity of these precursor materials.

The tech owner has developed a hybrid manufacturing technique that involves both additive and subtractive manufacturing methods. Instead of powder or filaments, sheets and foils are used as precursor materials, thereby alleviating cost, safety and performance concerns that were outlined. A laser is used to cut and fuse the different layers of the build.

Numerous tests conducted by the team have consistently yielded parts that are dense and displayed high strength. The system is able to work with different materials, including highly reflective ones such as stainless steel, aluminium, copper. Based on initial estimates, this technique offers up to 30% - 50% cost advantage over powder bed systems. The tech owner is seeking partners to collaborate in test bedding the system for manufacturing of complex, customised and/or high strength / high thermal conductivity parts for applications in the healthcare, semiconductor, aerospace, automotive, telecoms or marine & offshore sectors.

TECHNOLOGY FEATURES & SPECIFICATIONS

Print performance specifications:

- Smallest feature that can be printed - 50um

- Highly dense structure <= 0.5% porosity

- Surface finish of Ra <4 μm

- Complex structures with overhangs

- Powder free, enables fully-enclosed spaces and channels without need to powder removal

Printer specifications:

- Build Area – 125 mm x 125 mm

- Desktop printer to plug-and-play

- Compact footprint of 1m x 1m x 1m

- Energy deposition module that is based on commercially available laser source

- In-house proprietary slicer software and printer controller software

- In-house developed precursor material handling module

POTENTIAL APPLICATIONS

- Heat exchangers – micro cooling channels

- Semiconductor equipment

- Dental/bone implants; prosthetics; surgical tools

- Aerospace parts

- Automobile parts

- Mobile Device parts (e.g. Smartphone, laptop, smartwatch shells and casings)

Unique Value Proposition

- Unlike powder bed system, there is no need for expensive environment controlled chambers

- Safer and cheaper precursors (sheets and foils vs powder and filaments)

- Printed parts are higher strength (Example – Stainless Steel SS304L, up to 1 GPa yield strength)

- Printed parts are fully dense (<= 0.5% porosity)

- Lead time is significantly reduced for fully solid designs

- Can fabricate enclosed channels

- Surface roughness is 3 times smoother than powder bed techniques

- Minimal post-processing (e.g. sand-blasting) is necessary

- Compatible with different material classes (composites, metals, polymers, ceramics)