When Xander Sim, the inventor of Quiz biochip-based PCR, co-founded Cell ID in 2014, he had one goal in mind – to combine engineering and biological sciences to deliver fast, accurate, affordable and mass-deployable diagnostic solutions for home and near-patient use.

As the medtech firm’s Chief Technology Officer (CTO), Sim oversaw the R&D for several products. This included Cell ID’s flagship biochip-based PCR test kit for HIV viral load, malaria parasitaemia, nucleic acid test (NAT) for COVID-19 extracted ribonucleic acid (RNA) and one-step (OS) COVID-19 saliva tests.

“Ensuring that the test kit could be massproduced and affordable proved to be one of the most difficult challenges during the design phase as it involved using functional printing as the primary manufacturing method,” explains Sim. This meant that the company had to scout around for potential industrial partners with the capacity to use functional printing for mass production yet keep costs relatively low. Cell ID’s selected partner needed to appreciate that more trials were needed to produce medical grade diagnostic devices through functional printing too.

With this weighing on his mind, Sim joined a functional printing roundtable discussion organised by IPI. “IPI has shown that they have the resources and connections to pair SMEs up to exchange knowledge and promote collaboration,” he says. “So, we hoped that they could do the same for us.”

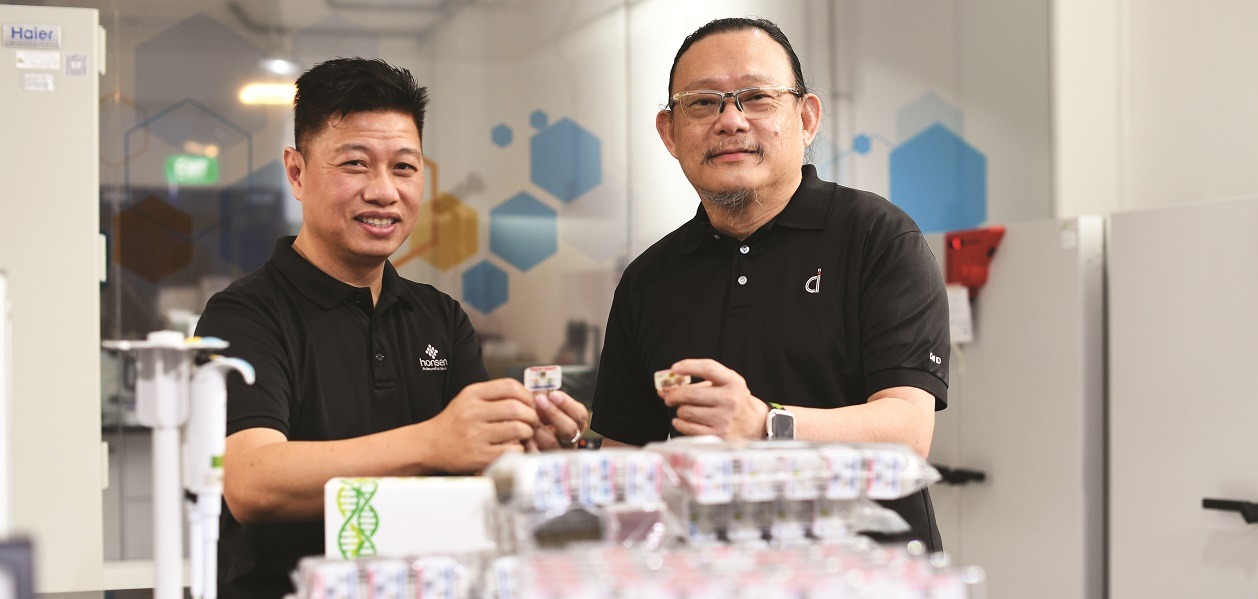

Sim was not disappointed. At the meeting, IPI introduced him to Honsen Printing, a high-tech printing firm that had the required expertise and technology to help. Importantly, they shared Cell ID’s vision of bringing a 100% made-in-Singapore product to market by developing and producing it locally through partnerships with homegrown capabilities.

Although they had no experience in biosensor printing at the time, Honsen played an active role throughout the research process, readily accepting and incorporating feedback to meet Cell ID’s requirements. Explaining their can-do attitude, Honsen Executive Director Kief Lim says, “Sim was very open in sharing his knowledge and helping us pick up functional printing within a short time. His faith in us and encouragement, together with our confidence in their products, made us redouble our efforts to make this collaboration a success.”

Honsen even stepped up to assist in the development of Cell ID’s biochip. When Sim made an off-hand remark about an issue his team had with a sealing mechanism, he was surprised when Lim volunteered a solution, thus helping Cell ID overcome a milliondollar roadblock. This mutual trust in sharing proprietary information and know-how is the key factor Sim attributes to the success of their partnership.

Thanks to Honsen’s support, Cell ID launched the world’s first fully printed biochip-based PCR using conventional large-scale functional printing techniques in December 2020. The company is now working on optimising the biochip for home use and is exploring its application in chronic disease diagnostics. “As we push to be a leader in affordable molecular diagnostics outside of the traditional lab setting, we hope that our products can be used at home within the next few years and see extensive deployment in low-to-middle income countries.”

Cell ID and Honsen’s shared experiences have cemented their belief in collaborations. “Exchanging knowledge and leveraging a partner’s capabilities without needing in-house development is an arrangement that will benefit all parties, especially for high-cost items like technology design and development,” Sim says, firmly. “Open innovation is something every company can learn and benefit from.”

Nodding in agreement, Lim adds, “Partnering with Cell ID has unlocked our true potential and capabilities in functional printing and opened us to new business opportunities. This is yet another step in our learning journey that began in 1995. We will constantly look for more opportunities to collaborate with other companies and build our knowledge."