When Robin Low, CEO of ARB Technologies (ARB), stepped through the doors of TechInnovation 2018, he was full of anticipation about meeting an innovation scout from Mitsui. It was his first time presenting his company to such a large MNC and one that could open new doors for the business.

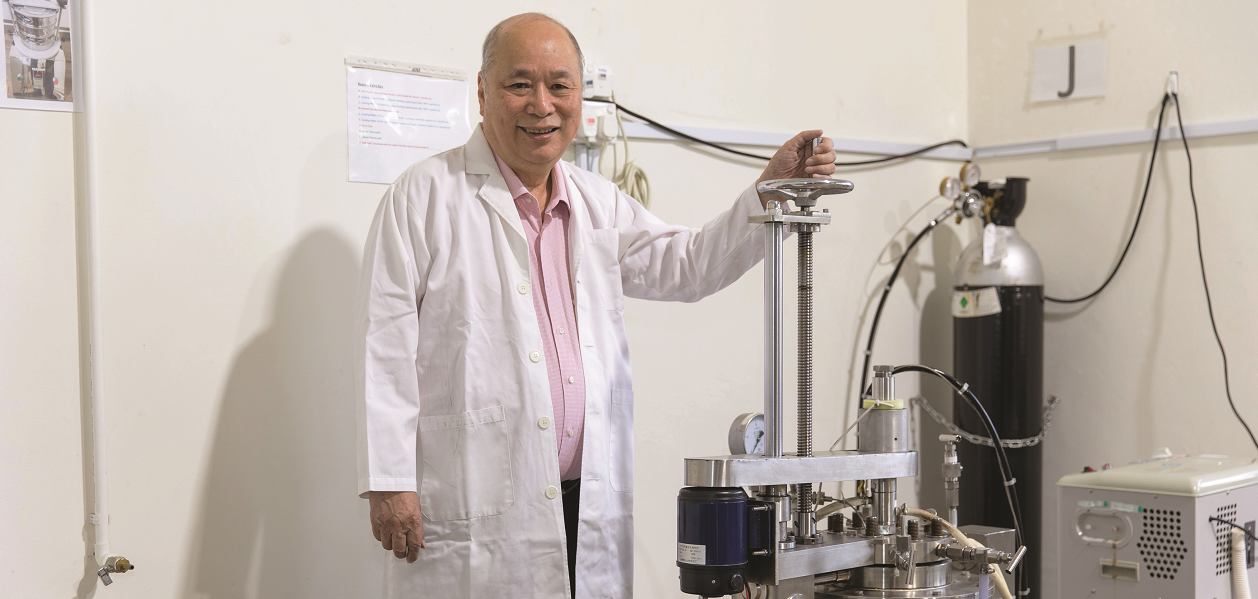

Following its inception in 1995, ARB evolved from focusing on electronics to specialising in innovative, cost-effective solutions in biotechnology and life sciences. For several years, it had been researching and commercialising novel technologies in green chemistry, transforming them into quality, market-ready products for global markets. While ARB had the experience and expertise, they needed to connect with like-minded strategic partners, locally and overseas.

The meeting with Mitsui, set up by IPI, was designed to do just that. Confident of his company’s in-house research and manufacturing capabilities, Low introduced ARB’s anti-microbial composition to the trading and investment firm, which immediately recognised its potential to create high-value products.

Around the same time, Mitsui was looking to convert shrimp waste from its farm and processing plants in Vietnam into the higher value product, chitin. ARB’s core technology could convert this into chitosan, an even higher value biopolymer which has multiple applications. At IPI’s urging, Mitsui began talks with Low to tap ARB’s experience in handling and processing biopolymer materials. “IPI played a crucial role in bringing together Mitsui and ARB. This development project gave us the opportunity to showcase our R&D capabilities and demonstrate what we are capable of,” says Low.

Both parties kickstarted negotiations on the agreement to invest in this project, with IPI offering ARB advice related to IP along the way. With the research collaboration agreement signed in July 2020, work on the project began.

Beyond benefiting Mitsui, the partnership was also useful to ARB. “We use chitosan in our final products so the project is quite synergistic. Our work in this area offers multiple licensing opportunities as well as potential commercialisation of the green chemistry manufacturing process, creating value from waste for a sustainable and resilient future. We expect new revenue streams as a result of this project,” explains Low, confidently.

The experience of teaming up with a large MNC from R&D to commercialisation also gave ARB important insight into understanding their customers’ requirements, mindset and company culture while honing their skills to meet their expectations.

Inspired by the success of the collaboration, Low is even more excited for the future of ARB. Plans are underway to make ARB a leading global player in sustainable natural biomaterials upstream and excellent finished products downstream, thus fulfilling their goal of becoming a vertical one-stop shop for sustainable living − all expected to complete within the next five years.

As Low and his team press on towards their dream, they have plans to further tap on IPI’s network and expertise too. “We are always on the lookout for new technologies and potential technical collaborations,” he says. “IPI’s role in matching local enterprises with multinationals is critical in growing SMEs like us into larger companies with stronger value propositions. I look forward to engaging their assistance in the future.”